20 November 2024

Results feasibility study on hydrogen network in Brainport region presented

- Energy

- Cooperation

- Scaling up energy innovation and products

- Transitioning to hydrogen

- Grid congestion

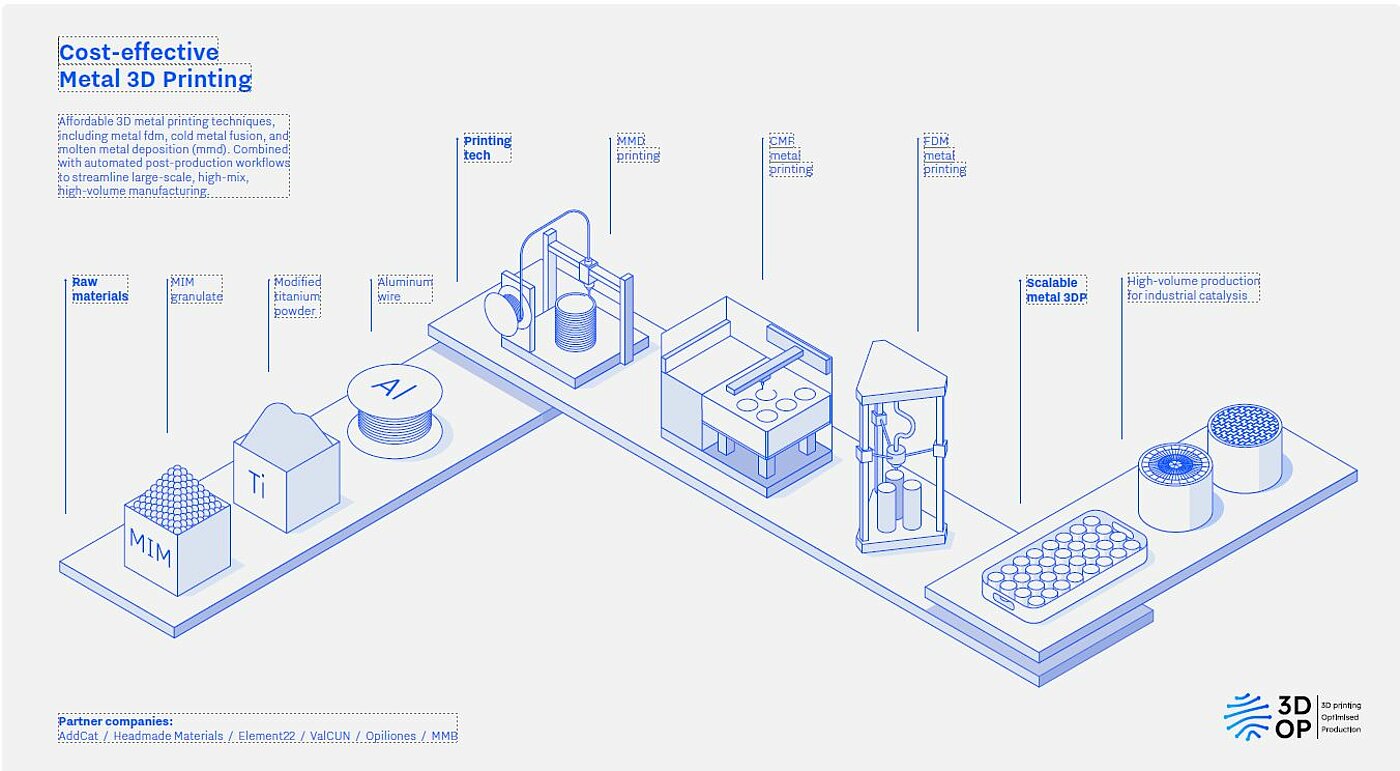

Two innovative printing techniques are being developed: metal FDM printing and molten metal deposition (MMD). These techniques are answers to the extreme costs and inherent incompatabilities that exist in several mainstream metal 3DP technologies.

One of the standout aspects of the metal 3DP effort in 3DOP is its focus on automation. The collaboration with other teams across the project, which centers on automating post-production workflows, is critical for ensuring that the entire 3D metal printing process—from production to final handling—is efficient and scalable. This integration of advanced 3D metal printing with automated systems positions WP2 to deliver solutions that can handle large-scale production more effectively.

The project also aims to develop modular production systems that allow for flexibility in manufacturing, enabling different materials and methods to be used within a single, automated framework. This modular approach can accommodate high-mix, high-volume production, which is essential for industries that require a wide range of custom components.