News

8

minutes reading time

11 Dec 2025

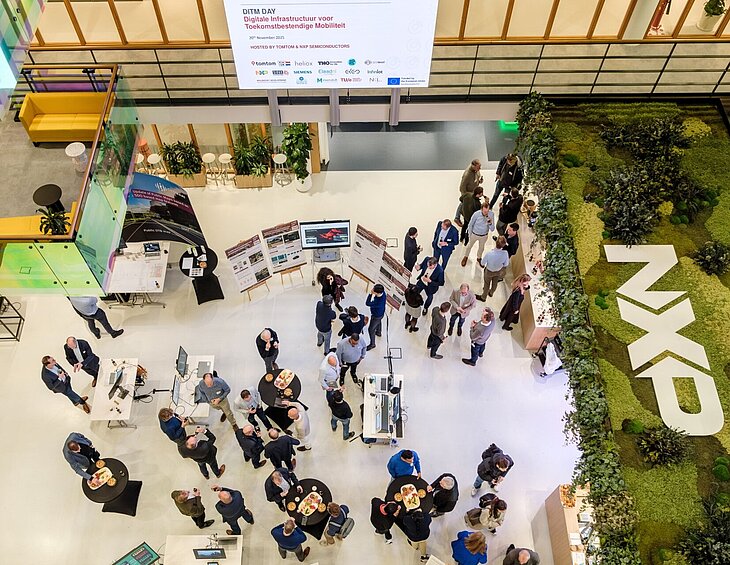

DITM Day 2025: working together to keep making real progress

DITM Day 2025 brought mobility professionals to Eindhoven to share progress and accelerate innovation in digital infrastructure and autonomous driving.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/e/2/csm_markant_partnerfonds_1920x1527_5d768a15c5.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/f/csm_20251118_Blue_Magic_Preview_LR_027_9X3A6073_7d520ca14f.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/6/csm_20251118_Blue_Magic_Netherlands_HR_107_013A1993_5028ffdb48.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/d/e/csm_20251118_Blue_Magic_Netherlands_HR_108_9X3A5770_5fb95586c8.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/7/csm_20251118_Blue_Magic_Preview_LR_005_9X3A5650_1__960204841a.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/0/csm_20251118_Blue_Magic_Netherlands_HR_228_9X3A6255_aaeaf72c42.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/c/csm_Qurmit_Partnerfonfs_1280x1920_b707d5ed3c.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/6/csm_Holla_publicatiefoto_1_707a67f19c.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/2/9/csm_Research_suquare_deelname_0c052c827e.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/e/7/csm_GNT_publicatie_1920x1280_1796e36100.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/1/csm_Defensie_vdl1250x833_b8537ecbbd.jpg)