LionVolt: from Gerard & Anton Award to safer batteries for the entire automotive industry?

LionVolt's solid-state solutions should significantly increase the safety of batteries, for example when used in aircraft and cars.

A new round of Gerard & Anton Awards is approaching. On August 31, the awards for the most promising start-ups from the Brainport region will be presented for the ninth time at the High tech Campus (you can register here). Last year LionVolt was one of the winners.

Eindhoven-based LionVolt is going to bring solid-state batteries to the market. This should significantly increase the safety of batteries, for example when used in airplanes and cars, as flammable liquids are used today. In addition, solid-state batteries offer other advantages. For example, they can be charged faster than current lithium-ion batteries.

LionVolt may not be as far along in terms of development as LeydenJar or Elestor, but the potential is certainly there. The company has only been around for three years, but is building a product that is showing impressive test results. CEO Karl McGoldrick explains where his team currently stands.

What specific problem are you trying to tackle with LionVolt?

"Batteries are essential for a sustainable future. With the existing lithium-ion batteries, we cannot electrify the automotive industry on a large scale. For that, we need batteries that charge faster, have a higher range and are less harmful to the environment.

But there is another, lesser-known problem the industry must deal with. Batteries can catch fire. The chance of that happening is about one in a few million. Now you don't hear about that very often, but with the massive growth of electric vehicles and wearables, it's going to happen much more often in the future."

And you are working on a battery that is safer?

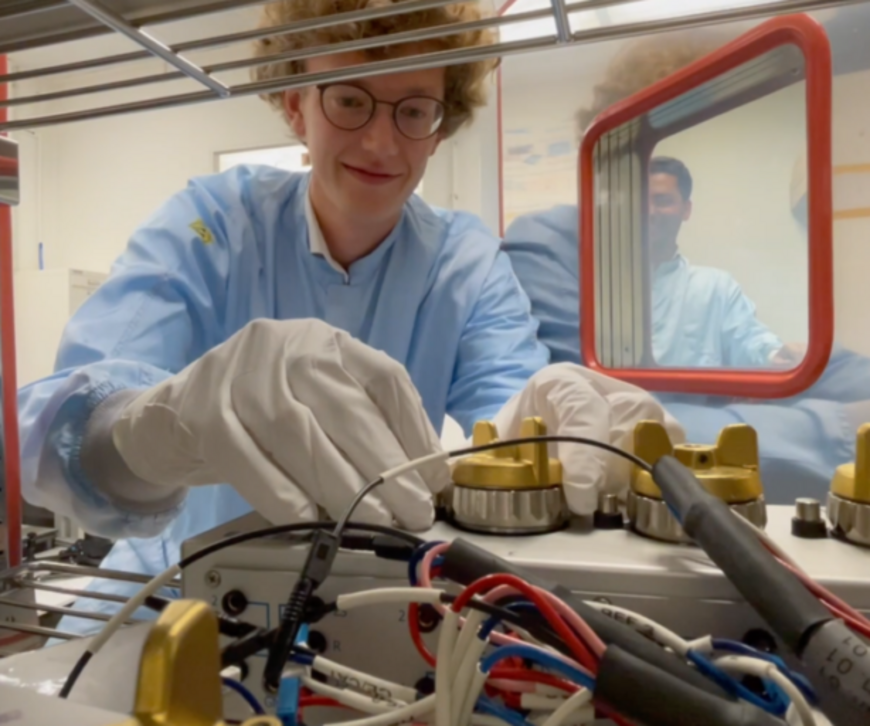

"True. In lithium-ion batteries, the current between the anode and cathode is guided by a liquid substance, and that's where short circuits sometimes occur. Major players in the industry have been announcing improvements for at least a decade, but constantly see their newly developed prototypes crash. Making samples still works, but high-volume production proves very difficult. We have succeeded by using thin-film technology to replace the liquid with a solid."

"Batteries are essential for a sustainable future."

CEO Karl McGoldrick

Battery in three dimensions

McGoldrick saw an initial concept of that technology at Holst Centre, the research facility of TNO and imec at the High Tech Campus in Eindhoven. The Irish native previously worked for Philips NatLab, Intel in Silicon Valley and Philips Semiconductors, the forerunner of NXP, among others.

The idea for a safer battery never left him and so McGoldrick, together with CTO Sandeep Unnikrishnan, started LionVolt in 2020.

"In the existing generation of batteries, charging capacity is linked to surface area. Just unscrew your phone or look under an electric car. We are the people who stood in New York 150 years ago and found that there was no more room to build. Someone then said: let's take to the air, let's build skyscrapers. With that we'll get a higher density of people in the same area."

Minuscule skyscrapers

So LionVolt applies this principle with batteries. The company stuffs these with micro units, tiny skyscrapers actually. The result is a smaller battery with a much higher energy density. Thus, in theory, an electric car should be able to drive thousands of kilometers on a single battery.

Yet the company is not focusing on performance at this stage. "Our roadmap starts with safety and goes from better performance to lower cost and eventually a more sustainable battery," he said. Unlike lithium-ion batteries, our design does not use chemicals and cobalt, a raw material that is already becoming scarcer."

So for now, a battery that can hardly catch fire is the important objective. The solid that LionVolt uses to conduct the currents should ensure that. In any case, the test results offer hope. A lot of hope actually.

"The test results at least offer hope. A lot of hope actually."

CEO Karl McGoldrick

Pilot plant under development

But first, further development is needed. With funding from Innovation Industries, the Brabant Development Company, Groeie Grutten Impact Fund, Brabant Startup Fund and Sake Bosch of Prime Ventures, among others, LionVolt is busy testing the technology in the lab. Yet the company is not going the usual startup route to eventually arrive at the market as its final destination.

"Normally there is the investor who says: develop the technology completely first, then we will look at industrializing it. We take a different approach. The Ministry of Economic Affairs and Climate and the Growth Fund have made 5.8 million available to start building a pilot production line now. With this support, we can industrialize much faster than is usual with new technology."

Early next year, the company plans to start delivering the first samples to a select group of customers, who have already submitted their specs. Their review is the next big step, on the way to a product-market fit. These are parties active in the wearables market, such as watches and medical devices.

Only at a later stage does LionVolt want to start testing electric cars. Major players in this billion-dollar industry have already expressed interest. They see in LionVolt an opportunity to significantly update the range of their vehicles.

More Dutch startups are working on so-called next-gen batteries. Do we have gold in our hands?

"Potentially yes, I believe in that. Batteries are at the point where the semiconductor industry was 35 years ago. Every country wishes it had invested more in developing chips. ASML's technology is crucial for parties in this global industry and serves as a kind of control point. We need companies in Europe that can play a similar role in the battery sector. I know this sounds like the ant saying it wants to become an elephant, but LionVolt has this ambition.

Because of the battery shortage, big players are focusing entirely on scale. As a new party, we can still really innovate. Moreover, there is so much specific knowledge in this field here in Eindhoven that you can't find anywhere else in the world. So gold in our hands? Yes, absolutely.'

(The core of this article previously appeared on MT/Sprout and was reproduced with permission)