A fridge, but for chips: this Eindhoven-based company helps save energy-hungry data centers

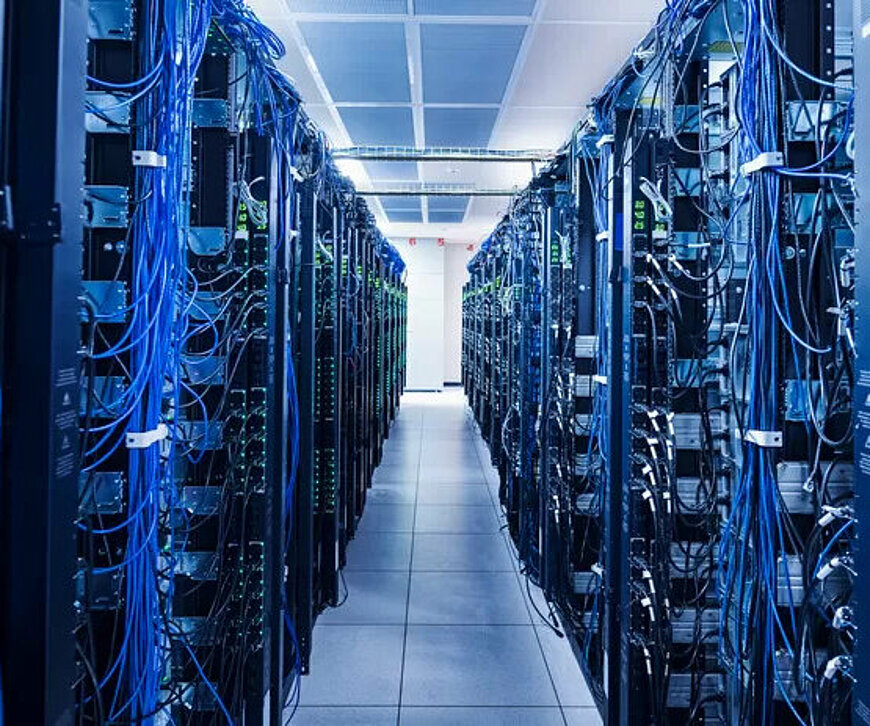

Everything and everyone today is connected to the Internet. Big data centers keep us online. That costs tons of energy, and more and more. Incooling from Eindhoven came up with a clever way to save energy.

Actually, Incooling makes a kind of refrigerator. Only not for keeping milk fresh, but computer chips. These also benefit from cooling. Do they get too hot? Then they lose power and speed. That costs energy.

And energy is expensive and increasingly scarce. Network operator Tennet is even taking into account a shortage of electricity after 2030 as more and more renewable energy becomes weather-dependent. Meanwhile, data centers will only eat up more power in the coming years.

"For every online meeting there is a server simmering somewhere, that requires power, a place and precious materials like gold and copper."

Rudie Verweij, Co-founder Incooling from Eindhoven, Netherlands

3.5 million euros

What Verweij wants to say: nothing is free. Although when sending data, it sometimes seems that way. With the push of a button, you digitally send a photo, no charge. And another. And another. And another video after it.

"The materials you need for that are not infinitely available. So the better we cool computer chips in a data center, the fewer chips we need in the end."

They also realize this at Pierburg Pump Technology, which is part of German arms manufacturer and automotive supplier Rheinmetall. That company is investing 3.5 million euros in Incooling. The two companies will further develop the Eindhoven invention together and the Germans will help with production in the future.

Just like a refrigerator

About that invention: to cool chips effectively, Incooling uses phase differences. "Converting liquid to gas costs energy. We use the heat from chips to convert liquid," says Verweij. ''As a result, the chips cool down and work better. Then we convert the gas back to a liquid that goes back towards the chips. It's a closed system."

Sound familiar? Could be right: a refrigerator works on the same principle.

Substantial savings

Incooling makes a kind of cooling block that it clicks directly onto the chips. Now data centers are cooled with air. That's enormously expensive and inefficient. With Incooling's system, that process becomes a lot more effective. The company claims that it can make equipment work 20 to 40 percent faster. Verweij: "That translates to energy savings of about the same magnitude."

That would require companies to start using the system from the High Tech Campus-based Incooling. But implementing the cooling blocks in existing servers is complex. That's why Incooling nowadays supplies entire servers where the cooling system is already built in. Verweij: "You buy a server, put it in your data center and you can turn it on right away."