New developments for the URE19

This year, University Racing Eindhoven (URE) is all about innovation and optimization. Every choice, design, and component has been carefully developed to take the performance of the URE19 to the next level. From a completely new suspension system to an optimized monocoque and extensive wind tunnel research; no detail has been overlooked. And with the arrival of our new, lightweight converter, we are taking a big step towards a faster and more efficient race car. In this blog, we will take you along the most important developments and milestones of our project this year.

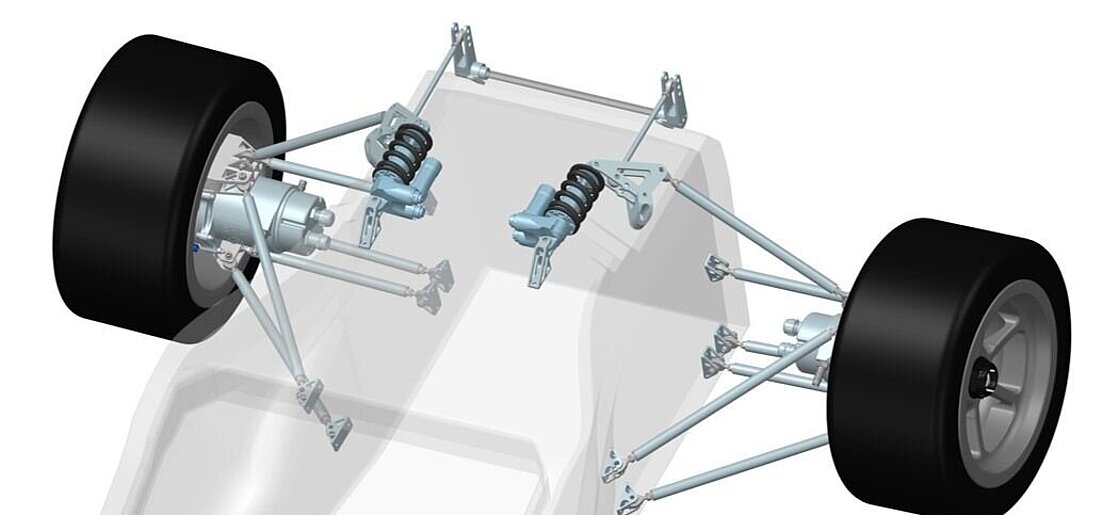

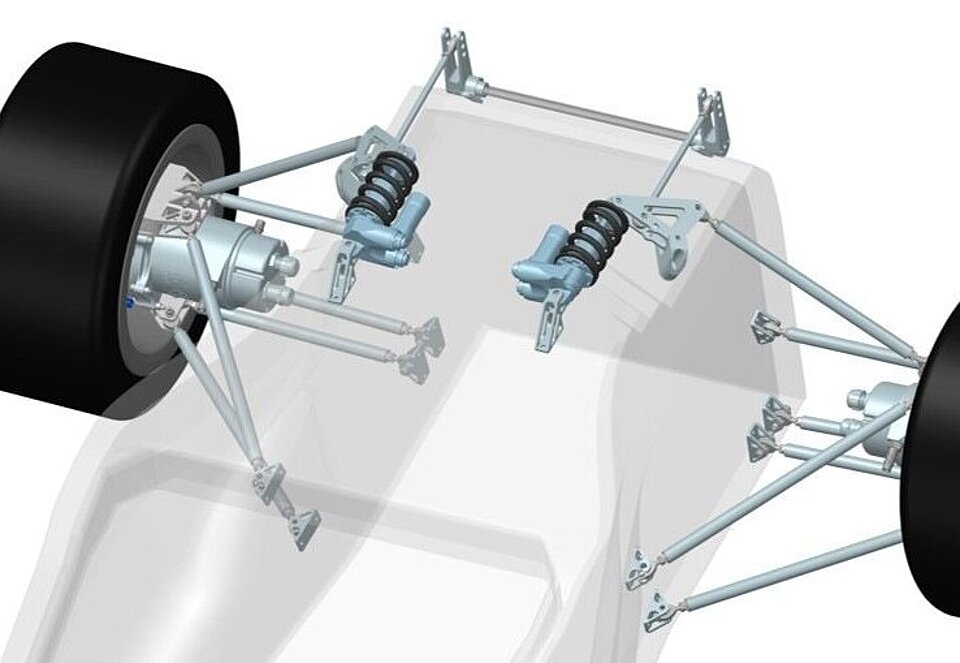

Suspension system

The URE19 gets an adjustable anti-roll system front and rear. For this the monocoque has been modified, because the system requires space on top. The challenge was to keep everything compact, without sacrificing visibility and knee room for the driver.

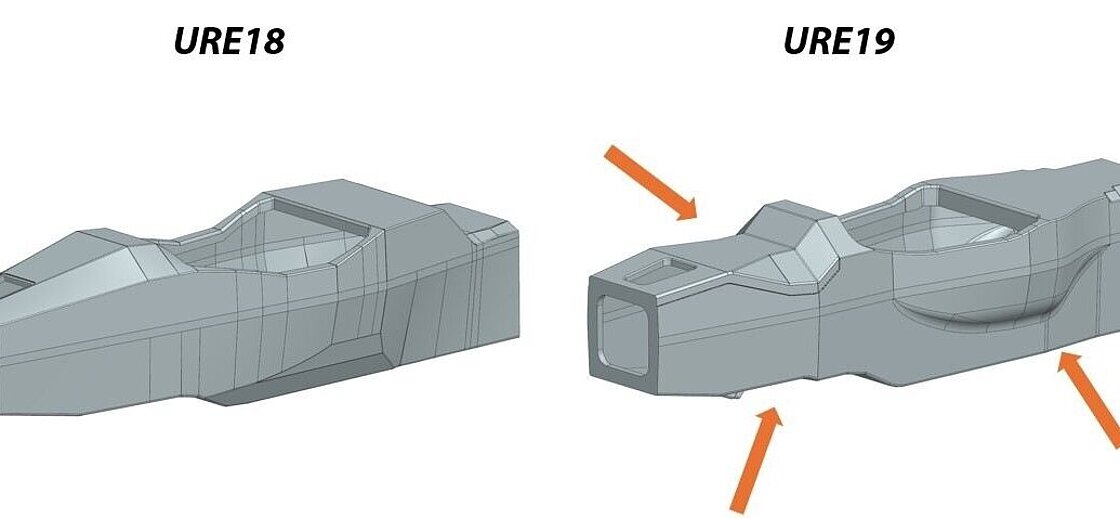

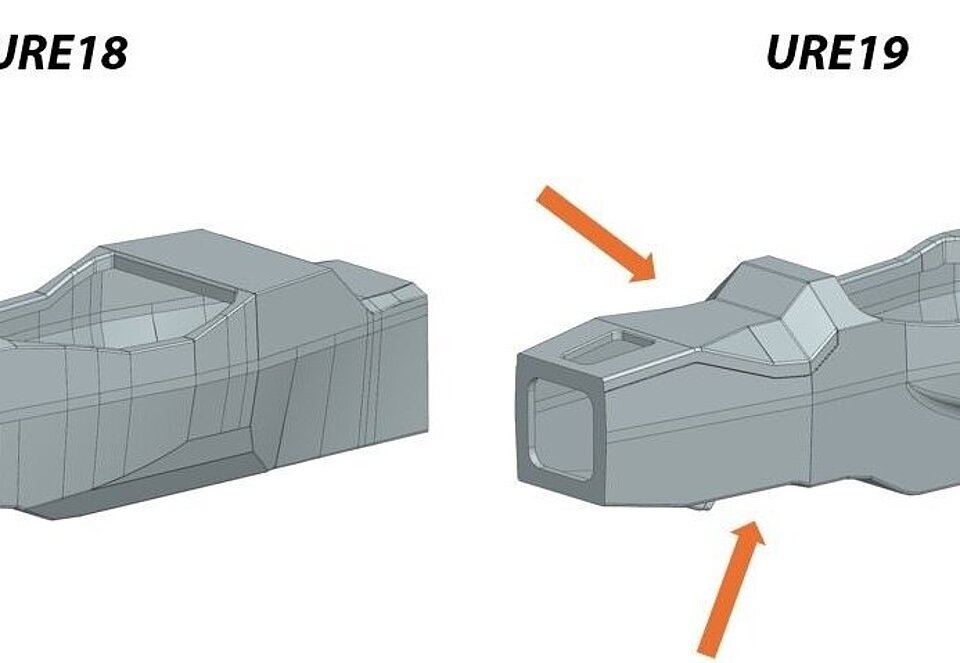

Monocoque

The biggest change this year is the monocoque of the URE19. As mentioned earlier, the monocoque had to be modified due to the new suspension system. However, this is not the only thing that has changed. More space has been created for the driver and the seating position has been adjusted. The new monocoque is narrower and lower, but longer so that the driver’s legs fit more easily than before. There is also more space around the steering system, which allows for a larger steering angle. Finally, the aerodynamics of the monocoque and nose have been looked at, making the rear end slimmer. All of these changes result in a more optimized monocoque, which ultimately allows us to drive faster and more efficiently.

Wind tunnel testing

To validate Computational Fluid Dynamics (CFD) simulations, a 40% scale model of the URE18 was tested in the wind tunnel. More than 50 configurations were tested, varying ride height and wing settings, among other things. The results are now compared with the simulations.

Inverter on the test bench

A big step: the new inverter is 50% lighter and 25% more compact. After years of development, it is finally here. The inverter has been successfully tested on the test bench and can control two motors simultaneously. It will soon be placed in the URE18 for further testing.

Teamwork

All these changes wouldn’t be possible without teamwork. Working in a student team means long evenings, lots of learning, and most of all: passion. We don’t just tinker, design, and test together, we celebrate successes and overcome setbacks as one team. Whether it’s a repair that needs to be fixed late at night or the moment you see the car driving for the first time – it’s still magical.

The URE19

All these innovations and improvements come together to form the URE19. The new suspension system provides better control and stability, while the modified monocoque makes the driving experience more comfortable and efficient for the driver. Thanks to wind tunnel testing and aerodynamic optimizations, the car glides through the air even tighter, with less resistance and more speed. And with the new, lighter inverter, we take an important step towards a more powerful and reliable powertrain.

Everything is aimed at being faster, more agile and more innovative than ever before. The URE19 is the result of months of hard work, testing and optimization by a team that always goes the extra mile. We are ready to show the performance of the URE19 – on the test bench and on the track!

TU/e Student Teams: Innovating for a Better Future

URE is part of the TU/e innovation Space – a dynamic hub for Challenge-Based Learning and entrepreneurship, where interdisciplinary Student Teams take on real-world problems, from clean energy to healthcare, to deep space exploration. Working with researchers, industry partners, and fellow students, teams like URE help to shape the future of technology in the Brainport Region.