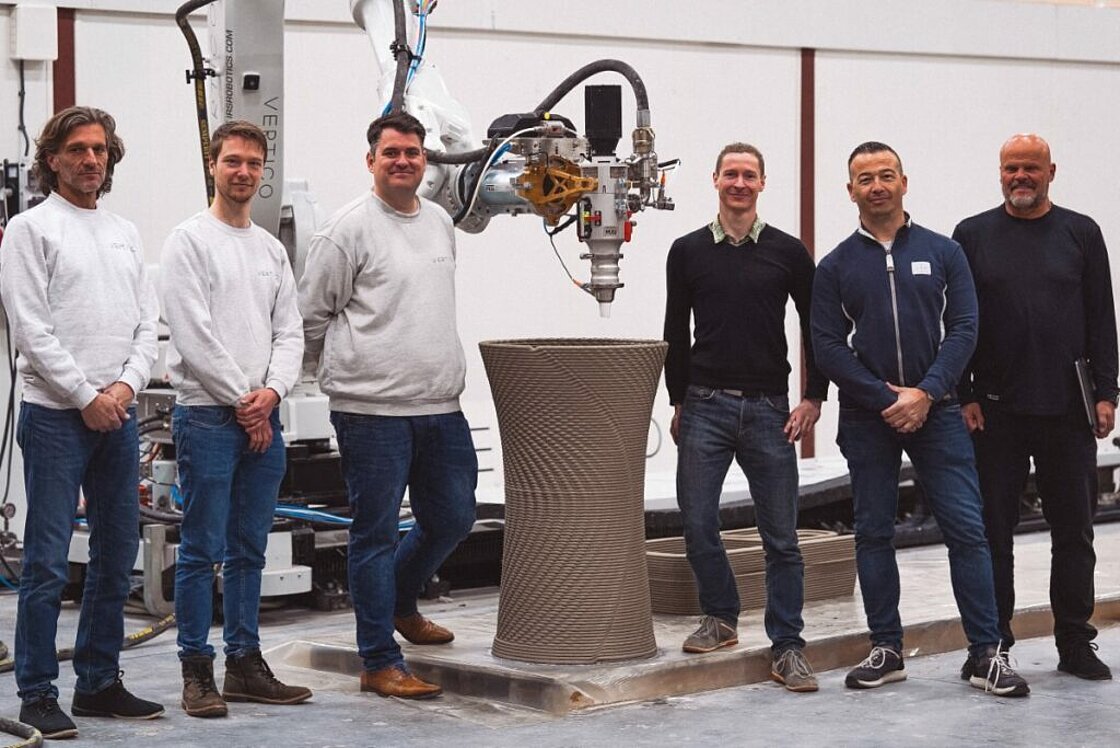

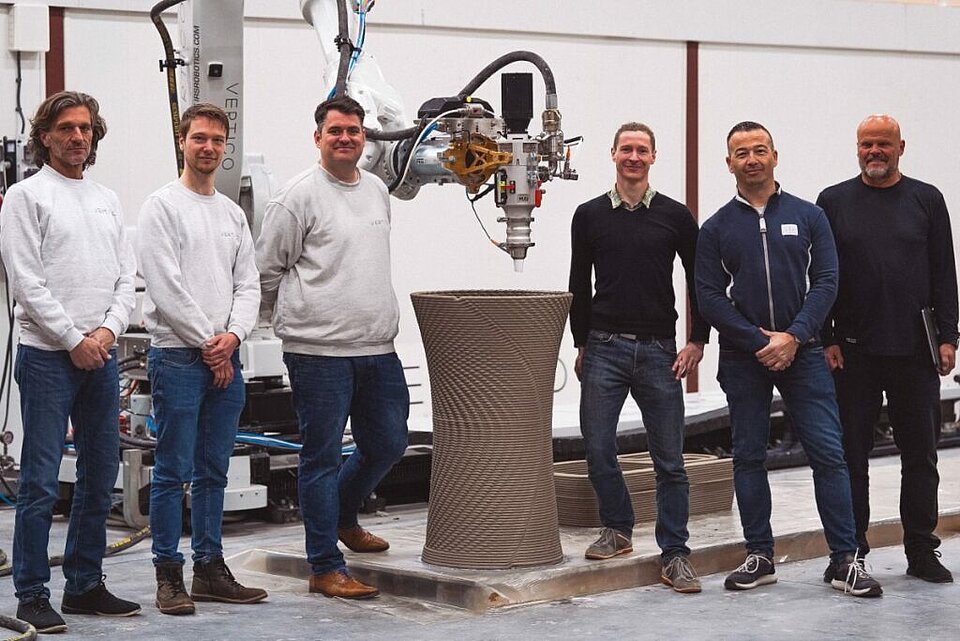

Vertico and Mai industrialize 3D concrete printing

Eindhoven-based Vertico and Mai of Austria say they are taking an important step toward industrial 3D concrete printing. The Accelerator Printhead Solution ensures high mixing quality of the components for the concrete mix. The new software can monitor the printing process in real time.

Austria's Mai has particular experience in the development and construction of mixers and pumps for the concrete industry. This expertise has recently been combined with Vertico's knowledge in robotics, software and print heads for 3D concrete printing. "The complementary areas of expertise and corresponding visions for the development of the concrete market meant that we were able to maximize potential," says Hannes Papousek, CEO of Mai International. Together, they now bring a total concrete printing solution to the market.

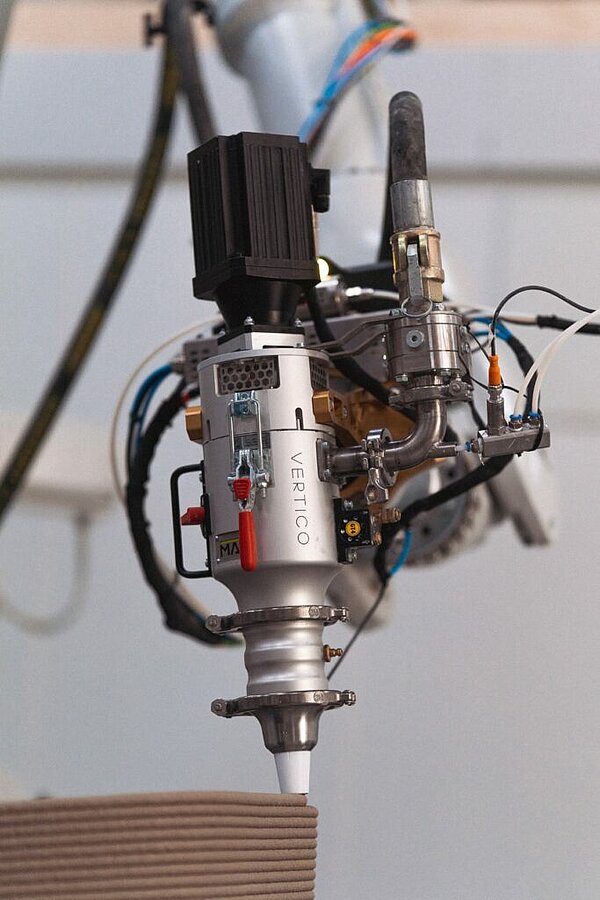

Blockage of printhead practically eliminated

The Accelerator Printhead Solution consists of a 1K printhead for concrete printing, a quick-change head, a set of pressure and temperature sensors as well as sensors that measure humidity, flow rate, motor torque and other factors. This improves mix quality, eliminating distortions during 3D printing. Clogging of the printhead inlet is also rare Thanks to a patented borrowing system, the printhead can be cleaned with minimal operator intervention. Mai and Vertico speak of almost self-cleaning.

Renewed HMI

Operation and control of the printing process are done from the updated, central HMI. Herein and in the system's software is Vertico's specific knowledge. "As with any new technology, it is crucial to understand what is happening in real time. With our years of experience, we know what to look for and pride ourselves on a good user experience with monitoring and control," said Volker Ruitinga, CEO of Vertico.

The two companies are continuing their collaboration. For example, they are working on several add-ons for the printhead, including a system to add color and a rotary printhead.