Smart Factory: when digitization meets connectivity

When digitization meets connectivity, you enter the smart factory. As an essential part of the fourth industrial revolution (Industry 4.0), it aims to optimize smart manufacturing processes. The fully digitized manufacturing facility of the smart factory uses devices, sensors, machinery, and production systems to continuously collect and share data. The data is then used for better-informed decisions to improve processes as well as address any issues that may arise. The main thought behind this process optimization is to – ultimately – get better business results.

Artificial intelligence (AI), big data analytics, cloud computing, digital twinning, and the industrial Internet of Things (IoT) are the drivers that facilitate a smart factory. Thanks to these technologies, the whole production process, from supply chain management to manufacturing tools and even the work of individual operators, can be monitored and, whenever necessary, adjusted. The key benefits of this ‘factory of the future’ are fewer shutdowns, predictive processes, and optimized facilities, leading to cost-effective and efficient manufacturing.

Although the rewards of the smart factory are easy to recognize, not every employer will be able to justify the expenses against the benefits. The cost of upgrading equipment, setting up security systems, and retraining staff may be too high. The decision to make a factory smart needs to engage all areas of a company, but ultimately also needs to be based on an accurate comparison of whether it is worth it for your particular facility or business model.

5 steps to improving knowledge management in your factory (4Industry)

- Step 1 – Make your knowledge digital

- Step 2 – Structure it by and for the shop floor

- Step 3 – Get it just right with on-demand knowledge

- Step 4 – Slice your knowledge – small is beautiful

- Step 5 – Put knowledge to work, immediately!

(whitepaper via 4industry.io)

But how to decide when it’s time to step into a world that’s still a mystery to most entrepreneurs? It’s a question that’s on Mobiquity’s plate every single day. “It’s always about mitigating something we identify as a friction point”, says CTO Jieke Pan. “For example, when there’s unclarity in measuring productivity performance, uncertainty about creating new propositions, or even if you struggle to reach new customers. Some of these frictions are easy to recognize, but sometimes they can be quite challenging. How do you know that higher efficiency is feasible when you simply think there is no other way to operate your factory? I mean: to be able to change your process, it requires entrepreneurs to know about the opportunities and benefits of the results.”

Pan’s colleague, Client Partner Thomas van Schie, challenges factory owners not to fall for the hype. “We engage in smart-anything projects if there’s a right use case. You can add AI optimizations as much as you would like, but you’re always as strong as the weakest link, including the external dependencies. Doubling your production capacity does not necessarily result in double output or double revenue; making your factory smart only makes sense when the business, or value chain, as a whole can grow through it.”

Key benefits for improving knowledge management in a smart factory (4industry)

Capture tribal knowledge

Safekeep your collective knowledge and best practices in a database in case an employee leaves, retires, or falls ill.

Boost worker autonomy

Facilitate learning and reduce operator dependency. Empower them to act and make the right decisions in line with safety measures, procedures, quality controls, and policies.

Cut costs

Operators spend up to 18% of their time looking up information. Manufacturers who make information readily available can achieve considerable cost savings.

(whitepaper via 4industry.io)

Use cases for Mobiquity, a global company that is part of Hexaware and focuses on creating digital products and services, can always be found in the digitally connected world. Also, “experience” is a key differentiator, says Pan. “User experience, employee experience, business experience, you name it. Take, for example, the case we covered for a bank. Everybody knows the hassle you have to go through if your credit card gets lost. You have to call the bank, hoping that somebody’s there to help you. Remember your credentials, first dog’s name, or mother’s favourite dish. Then they disable your card, and the quest for a new one can start. It takes you at least some days before everything is working again. Thanks to the power of a smartphone, we could build a solution that fixes this in seconds and in a secure way. That’s what we mean by a better experience.”

That’s the same in the world of the smart factory, Van Schie adds. The whole experience needs to be worthwhile. “Whether it’s the user journey, the operator journey, or even the whole smart factory journey, it adds the most value if it’s covered end-to-end. Take the challenge around hydrogen production, a perfect example of having smart production processes. You should follow the hydrogen journey right from the start of the renewable energy source to the distribution of the product to the end-users and validate how intelligence can add value in this process. Smart manufacturing reaches its full potential when you consider the entire value chain. Only covering a part of the process might just give you a part of the benefits.”

Factory of the future

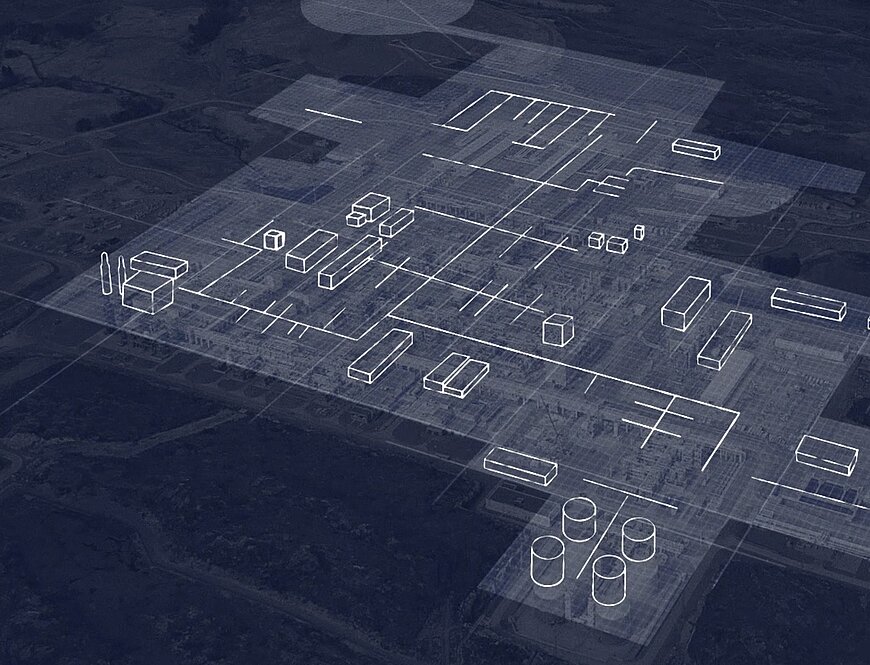

All around the world, so-called ‘factories of the future’ are being built. They aim to cover all the aspects that determine the smart factory principles. One of those future factories can be found at Brainport Industries Campus in Eindhoven. It covers various fieldlabs, innovation programs, and value chain collaborations. Companies, local governments, and educational institutes are involved. “The ultimate goal is a digital factory where manufacturers can track and adjust all their production processes in real-time if they want,” said Michel Weeda shortly after its start. More here.

Another challenge from Mobiquity’s experience: a factory can only become smart if the company involved has enough digital maturity. “If a company owner comes to us with just a vague wish to automate their production processes, we first try to find out where the real friction point is”, Pan says. “When we see a lack of digital maturity, we advise this company to cover the basics first. A factory can only become smart after it is digitized sufficiently.” On top of digital maturity, there needs to be business maturity, Van Schie adds. “That’s a foundational point: IT has to be supportive toward business objectives. IT in itself is not enough, it needs to link to your business, for example, to enable growth objectives, reach quality improvements or drive cost reductions.”

Conditions for (becoming) a smart factory (mobiquity)

- digital maturity

- potential better experience for the stakeholders

- clear business benefits

- covering the company’s whole value chain

- mitigating a painful friction point or crucial transition

This article is part of the AI Innovation Series, organized by the AI Innovation Center. The series focuses on the application of AI in the manufacturing industry. Learn more here.