LouwersHanique: 'Together with our customers, we do phenomenal things'

The Brainport region has countless high-tech manufacturing companies. Each with unique qualities. One of these typical Brainport companies is LouwersHanique, located in Hapert. What sets the company apart is its ability to process and particularly combine technical glass, ceramics and metal. This leads to high precision products and components that are essential in the semicon, medical technology and analytical markets. The company doubled in numbers of employees in recent years and sales also showed significant growth.

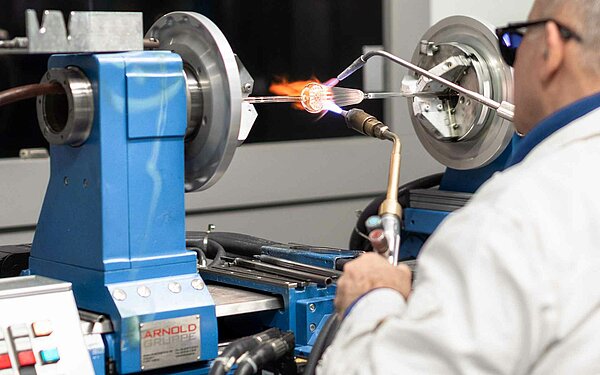

Kees Verspaandonk is Managing Director of LouwersHanique and has been at the helm of the company since last September. "LouwersHanique has been around for about 70 years," says Kees. "It is a merger company that, like several companies in the region, grew indirectly from Philips where glass processing played a prominent role. We started from glass machining and later ceramics and more recently metal were added."

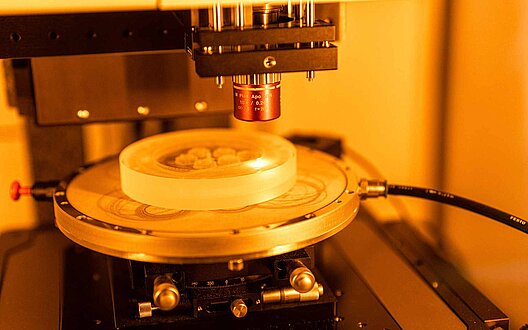

"Moreover, our machining methods have become increasingly sophisticated over the years, enabling us to manufacture parts, components and products with high precision. What particularly sets us apart as a company is that we can combine, or bond, those materials. You can see this, for example, in the flanges with connector connections that we develop, which combine exotic metals and glass. They enable our customers to build a bridge between an environment where vacuum processing takes place and outside it. "

Co-development with companies like ASML and FEI takes us to the next level

"Our customers consist mainly of Original Equipment Manufacturers (OEMs) and their suppliers. These are located in and far beyond the Brainport region," explains Carel van de Beek. He is Sales & Marketing manager at LouwersHanique where he joined the company some ten years ago. "The focus of our customers is in the German-speaking region and the Benelux, in addition we have customers in America and a handful of customers in Asia."

"Especially the OEMs in the region, think ASML, FEI and VDL Groep, have taken us to the next level as a supplier," Carel continued. "It's super to have companies like this in your immediate vicinity. Developing products and components often involves very long processes in which we think and develop from the design phase. This kind of co-development challenges us to continuously develop and look ahead." Kees adds, "here in Brainport you feel and taste the technology and the speed at which the world is developing. Our customers are doing phenomenal things and we develop along with them."

Enormous growth in sales and employees leads to greater visibility

The success of the Kempian company can be seen in the growth it has experienced in recent years. "Over the past 10 years, both our turnover and the number of employees have increased enormously," Kees says." From about 75 colleagues, we grew to more than 150 employees. More than half of them are assembly workers, clean room workers and operators, about 30 engineers and a few more colleagues in sales and support positions. This growth has also done something for our name recognition. Whereas we used to communicate with customers primarily through very direct channels, we are paying more and more attention to labor market communication and building broader brand awareness."

Growth is beautiful and challenging

"That growth is beautiful but also very challenging. We only expect more growth in the coming years. That means that we need more space and have to fill more vacancies in an already tight labor market. At the same time, we are trying to work very process-oriented and as efficiently as possible wherever we can. By automating part of the glass processing, for example. Blowing glass is craftsmanship but other repetitive operations can be automated and therefore scaled up. That requires more machines and therefore more space. We now have 3 buildings but the most recent one is almost full again."

"We are now looking at where we can expand even further."

Own employees are the best ambassadors

So far, despite the tight labor market, attracting new colleagues has never really been a problem for the company. "What struck me when I started here last year is that it is an incredibly people-oriented company," says Kees. "There is an enormous togetherness. I have rarely seen a company where people party so intensely. It's a fun company to work for. Moreover, the materials we work with are just a bit more exotic than, for example, at companies that only process metal. That makes it challenging for employees, requires creativity and makes the work fun. Our employees are therefore our best ambassadors!"