From diesel to hydrogen: the engine that puts The Netherlands on the world map

The transition to a climate-neutral energy system brings opportunities and challenges. However, you can make a difference with pragmatic thinking and innovative action. The Dutch company NPS Driven proves this. They are currently converting a traditional DAF engine into an innovative sustainable hydrogen engine for use in building, construction, and inland shipping.

Sustainability as a drive

“It is my drive to make a specific contribution to sustainability. I do this both at home and work. We borrow the earth from our children, so it is our job to come up with solutions for sustainability issues,” says Peter van der Heijden, Managing Director of NPS Driven. “Together with colleagues from TNO, four years ago, we started converting the traditional combustion engine into a clean alternative.

Modern diesel engines can run on hydrogen with some adjustments. The advantage is that such a system does not cause harmful emissions and is a cheap solution compared to batteries or fuel cells.”

It works excellent

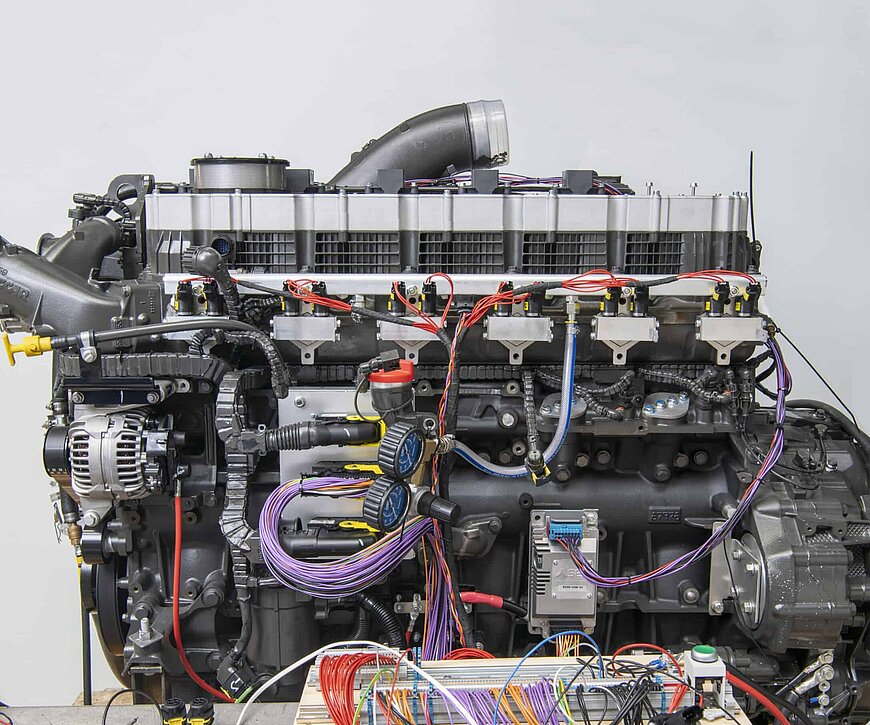

Jarne Lotens is an R&D Engineer: “When I heard that NPS Driven was serious about hydrogen, I knew I wanted to be part of it. I develop the components for the hydrogen engine, where everything is produced with millimeter precision. We almost have to completely dismantle the existing engine for this. We have developed our own fuel and ignition system that converts hydrogen into energy. The great thing is that everything works excellently. The engine on the test position at TNO proves that.”

Get started quickly

Chief Scientist at NPS Driven, Peer Wezenbeek, supervises the tests at TNO and makes adjustments where necessary. “It’s the software that makes sure the engine does what it’s supposed to do, and this test project should be completed at the end of this year. At the beginning of 2024, our first customers can already start working in the testing lab, where we conduct various field tests. After that, we will continue with the development and calibration so that we can deploy the set on a wider trajectory. That takes about a year. As a team, we put a lot of time and effort into staying at the forefront of this.”

Affordable sustainability

Peter van der Heijden: “Major players in the market want to reduce their CO2 footprint and are going to work with the transporter who can support them with this. Transporters who dare to take the innovation step now can meet this requirement quickly and with limited financial resources. It looks like the installation of a hydrogen engine is many times cheaper than electrification or fuel cells. Moreover, we can produce hydrogen ourselves in the Netherlands, eliminating the use of scarce raw materials. In addition, the hydrogen engine works practically the same as the diesel engine. As a result, maintenance is comparable, and market acceptance is high.

Nitrogen emissions are still causing construction delays. So they also benefit from engines for generators or excavators without CO2, nitrogen, or particulate matter emissions. The advantage of the hydrogen engine is that a service team learns how to deal with hydrogen within two days. Construction companies are therefore quickly up and running to work with hydrogen engines.”