Manufacturer of battery packs, ELEO, seizes the opportunities that 3D printing has to offer

For battery factory ELEO, 3D printing is the most normal thing in the world. It is an inseparable part of the production process.

Scale-up ELEO explicitly uses 3D printing to accelerate its development process. The Eindhoven University of Technology spin-off develops battery systems for, among other things, large excavators in the construction industry but also for smaller logistics vehicles in warehouses.

Ever since it started as student team STORM, in 2014, the company has been using 3D printers, says Jules Frints, a product developer at ELEO. Back then, the team received a printer sponsored by the 3D printing company, Lay3rs from Brainport Eindhoven, where his colleague and friend Stephan van der Burgh worked. The two are now the 3D specialists within the company.

"At first we wondered if we were really going to do that much with it”, Frints admits. “But we became so enthusiastic that at one point we bought one ourselves. And that one was replaced by a better version. Now we have two of them."

In 2016, the student team rode a homemade electric motorcycle around the world in eighty days. The motorcycle served as a showcase to show the world that it is possible to ride electric anywhere, said co-founder Bas Verkaik in an interview.

The company evolved and now, ELEO develops modular battery systems that customers can use in their own vehicles. A package consists of several modules and a controller. Frints: "We can develop it completely according to customer specifications. Depending on the customer's requirements for voltages, capacities, and volume, a package consists of one or more modules." ELEO is located at the Automotive Campus in Helmond.

3D printing is not an end in itself for ELEO, Frints continues. "In the development phase, it is very useful to be able to quickly prototype parts." At a later stage, these parts are made with injection molding. That technique has a much longer lead time than 3D printing. "You need a mold for it, which is pretty expensive to make. You prefer to get that mold right the first time. But even then, it can take a few months before the products are made."

Also, you're not dependent on a third party and you can quickly make something to test, Frints says. "It is nice to have a product in your hands at an early stage. It doesn't have to be good all at once. You can quickly fabricate something in a free form and then start fine-tuning it."

Of course, this first prototype won’t have the same accuracy or stiffness as the final material. Nor is that necessary in some tests, Frints says. For example, to see how sensitive a design is to electromagnetic radiation. "For that, it doesn't matter if I use a 3D printed or plastic injection molded part. For fire safety, vibration and shock tests, accuracy and material are important again."

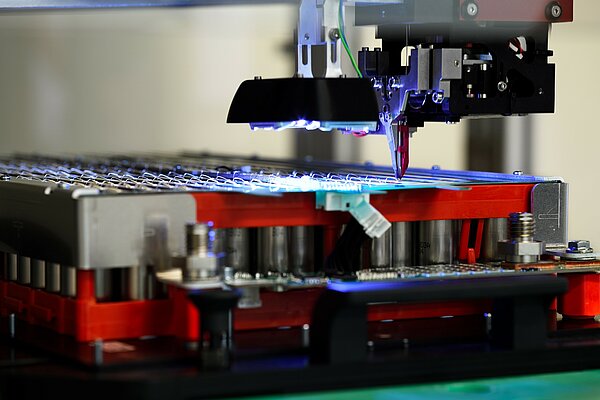

The 3D printer is completely woven into the company's production process, for prototyping and tooling. "For us, it's very normal to turn an idea into a 3D print quickly. Just this week it happened. We had to assemble several components and quickly printed a mold for them. Just to put the components in place."

Sometimes a 3D-printed part remains in the production line. "That never involves large numbers. But sometimes we print a part for a customer, for example to hold cables together, which then stays in there."

ELEO does not print all parts itself. "It depends on the function and required accuracy whether we outsource a print," he says. The company has an FDM printer and an SLA printer. If other printers are needed, Frints outsources that job.

"For example, a Multi Jet Fusion printer prints with a type of nylon. This allows us to make nicer and more precise products than we can with our own printers. It also depends on the geometry of a part. If the shape is too complex, we have a company that prints that for us as well." When the parts are small and strong, or large and rough, ELEO can print them without help from the outside.

Frints is now working on the prototypes of the new generation of batteries, which the company will launch later this year. For that purpose, the printed test version of a so-called cell spacer has been replaced by a variant made from a steel injection mold. "A few hundred thousand products can come out of that," he expects.