Smart and safe transport thanks to collaboration between man, machine and data

Within the DITM innovation programme, Dutch technology company V-tron is working with parties such as VDL, TNO and Monotch to make transport smarter, safer and more people-oriented. The company is developing technology that allows man and machine to work more closely together.

From connected cars to E-Trailers

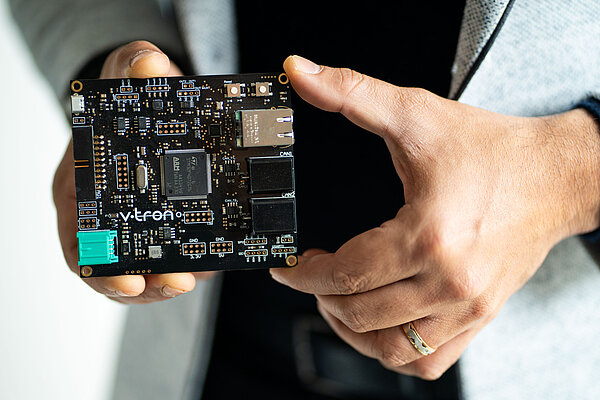

V-tron is a technology company that rests on two pillars: one commercial and one R&D-focused. The commercial branch supplies connected car solutions and driving behaviour analysis tools to companies in Europe and Africa. The R&D department is headed by Rakshith Kusumakar, CTO at V-tron and responsible for the company's technological direction and innovation agenda. His team develops new technology in three areas: vehicle connectivity, teleoperation and the E-Trailer.

‘In vehicle connectivity, we are investigating how vehicles and infrastructure can communicate better with each other,’ he says. "This has resulted in our road asset management system. We scan the physical infrastructure – such as traffic signs and guard rails – and compare it with digital maps. If there is a deviation, road authorities can immediately inspect and correct it. This ensures that the digital road infrastructure remains reliable."

The second area of research, teleoperation, focuses on vehicles in enclosed areas such as ports and distribution centres. ‘There, lorries drive in predictable patterns and short distances,’ he explains. ‘An ideal environment for automation or remote control. Within DITM, we apply the same principle to bus depots.’ Remote control is not always strictly reserved for humans; the necessary tasks are also automated, allowing one operator to control multiple vehicles in parallel.

The third theme is the E-Trailer, a trailer with its own battery and electric motor. ‘It can power itself and work together with the towing (diesel) truck,’ says Kusumakar. "The result is a hybrid combination. The trailer can be coupled to any existing truck, which will also reduce emissions from the existing truck fleet. In the future, these trailers will even be able to manoeuvre independently within a site. We are developing the software that controls everything: from the battery to the motor."

It can be said that V-tron is developing transition technology that is necessary to enable the step towards an autonomous future.

Between automation and control

The development towards autonomous transport is proceeding in phases. Between manual driving and fully autonomous movement lies a crucial intermediate phase in which humans and technology work together. This is precisely where V-tron's field of activity lies.

Within DITM, the company is active in two work packages: one focusing on teleoperation and one on Intelligent Speed Assistance (ISA).

In work package two, V-tron focuses on teleoperation of buses in enclosed areas, such as depots. ‘Every night, buses are cleaned, charged and parked. That process can be largely automated, but no system is 100% error-free,’ explains Kusumakar. ‘Teleoperation ensures that a human can intervene when necessary. An operator sees what is happening and can move the bus safely. Once everything is back to normal, the automation takes over. This keeps humans and machines in balance.’

‘Teleoperation is the bridge between humans and machines,’ he says. ‘We use the power of automation, but retain human control where necessary.’

In work package four, V-tron is working on technology for vehicle-infrastructure communication, including Intelligent Speed Assistance (ISA). ‘We use 4G and 5G to exchange real-time information between vehicles and traffic lights,’ says Kusumkar. ‘For example, the system can advise you to adjust your speed so that you get a green wave. That may seem like a small optimisation, but it has a major impact on safety, energy consumption and traffic flow.’

Technology in the service of safety

V-tron's technology is now also being used outside DITM. In Belgium, the company is working on a crash absorber truck, a vehicle that closes lanes during road works. ‘These vehicles are often used in locations with an increased safety risk,’ says Kusumakar. ‘With teleoperation, we can control the truck remotely without being physically present in the cab. This increases both safety and operational efficiency.’

These practical examples illustrate why V-tron is not only concerned with technology, but also with regulations. ‘Current traffic legislation is outdated,’ he explains. ‘In many countries, it is still stipulated that a driver must be physically present in the vehicle. We are contributing ideas for new frameworks that are in line with today's technological reality. Technology is developing faster than legislation, and it is essential that the two reinforce each other rather than hinder each other.’

Results within DITM

V-tron has taken concrete steps within DITM in recent months. “We have completed full integration for teleoperation,” says Kusumakar. ‘We demonstrated the system live during the Drive Forward event at the Automotive Campus. The next step is a large-scale demonstration at VDL, showcasing the entire process of cleaning, charging and parking in a single workflow.’

The results are also visible in work package four. ‘We have realised the link with the central Data Service Exchange,’ he explains. ‘This allows us to receive data from partners such as TomTom, Monotch, VDL and TNO. The first tests with real-time data streams have been successfully completed.’

One of the next applications is bus platooning, in which several vehicles drive close behind each other and are given priority at traffic lights. ‘The system recognises that a cluster of buses is approaching,’ says Kusumakar. ‘The traffic light stays green longer so that all vehicles can pass safely. That sounds simple, but it requires seamless cooperation between vehicle, infrastructure and data.’

The project will run until the end of 2026. ‘We have tested all the components,’ he says. ‘In the coming months, we will focus on the integrated trials in which everything comes together. That will be the real litmus test.’

The critical factor: connectivity

The biggest technical challenge is the reliability of the network and the data. ‘Teleoperation is completely dependent on connectivity,’ says Kusumakar. ‘With 4G, you can remotely control one vehicle, but not an entire fleet. 5G offers much more capacity and lower latency, but coverage is not yet guaranteed everywhere. If the connection fails, the vehicle stops automatically; that is our safety measure. Ultimately, you want the technology to be so reliable that intervention is no longer necessary.’

He considers teleoperation to be an intermediate stage on the road to fully autonomous driving. ‘Automation works smoothly in 98 per cent of cases. The remaining two per cent still causes doubt among users. Teleoperation bridges that gap. An operator can monitor multiple vehicles and only intervene when necessary.’

“This way, humans remain part of the system, but their role changes – from driver to director.”

Societal impact

This shift also creates new opportunities in the labour market. ‘Teleoperation makes the profession of driver attractive again,’ says Kusumakar. ‘Young people no longer want to spend weeks on the road. But if you can drive vehicles from an office or even from home, that perspective changes completely. It combines driving experience with digital skills – a new form of craftsmanship. And people who are distanced from the labour market can make the most of these new opportunities.’

Safety and health also benefit. ‘In ports, Bobcats (skid steers) are used to move bulk goods, sometimes containing hazardous substances,’ he explains. ‘Teleoperation allows operators to work from a safe space. They are no longer at risk, can work longer hours and deliver more consistent performance. That's better for both people and businesses.’

In addition, the technology leads to greater efficiency. ‘When a ship carrying hundreds of cars docks, each car has to be driven out manually,’ Kusumakar continues. ‘With teleoperation, a single operator can control that process remotely. This increases efficiency, reduces costs and minimises the risk of damage.’

A digital infrastructure that works

In the current project phase within DITM, V-tron is focusing on the reliability of digital infrastructure. ‘We have developed a system that detects traffic signs and compares them with digital maps,’ says Kusumakar. ‘If a sign is missing or has been registered incorrectly, the road authority is notified immediately.’

This accuracy is essential, especially now that Intelligent Speed Assistance is mandatory in new vehicles. ‘ISA combines camera images with map data,’ he explains. ‘If these do not match, a vehicle may brake incorrectly or give the wrong signals. We ensure that the digital data is reliable so that vehicles always use the correct information.’

V-tron wants to expand this system into a complete asset management platform that monitors not only traffic signs, but also lane markings and their quality. ‘We can now recognise more than 130 types of traffic signs,’ says Kusumakar. ‘By linking that data to HD maps, road authorities get a complete, up-to-date picture of their infrastructure.’

From lab to practice

In the next phase of the project, V-tron wants to make the transition from development environment to practical application. ‘The next step is to conduct practical trials with operational partners,’ says Kusumakar. ‘Bus companies, logistics centres, municipalities – we want to see how operators, drivers and managers deal with the technology. Practical experience always teaches more than the lab.’ He emphasises that cooperation within the consortium remains crucial. ‘The strength of DITM lies in the combination of parties. This collaboration allows ideas to be implemented more quickly and enables us to test technology in realistic environments.’

At V-tron, this literally happens on the road. ‘We test directly with cars, buses and lorries,’ he says. ‘The real world is never perfect, which is precisely why you have to test there.’

Collaboration with the education sector also plays a role. ‘We enjoy working with colleges and universities,’ says Kusumakar. ‘Students bring fresh ideas and have a practical mindset. That helps to translate innovations into concrete applications more quickly.’

Technology with a human purpose

or Kusumakar, innovation is not about technology itself, but about what it means for people. ‘Teleoperation is not about replacing humans, but about creating new possibilities,’ he says. ‘We make work safer, processes more efficient and mobility smarter. Technology should empower people, not make them redundant.’

He sums it up succinctly: ‘If we can use DITM to show that humans and machines work better together than they do separately, then we will have truly achieved something. That is the future of mobility.’

“If we can use DITM to show that humans and machines work better together than they do separately, then we will have truly achieved something. That is the future of mobility.”