Brainport company tackles network congestion with smart solutions

At the heart of the Brainport region lies a remarkable hub for metal treatment: the Centrum voor Verduurzamen (Centre for Sustainability). At this family business in Veldhoven, Brabant conviviality goes hand in hand with technical innovation and sustainable ambitions.

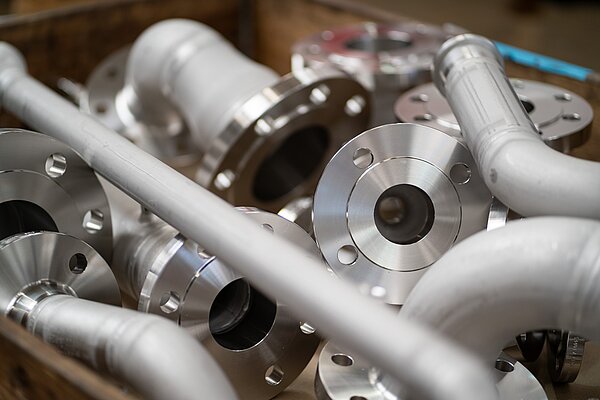

The centre consists of three companies under one roof: Verzinkerij Meerveldhoven, De Run Metaalcoating en Dameco Plating. Each company has its own specialism, but together they offer a complete range of surface treatments for metal. From thermal and electrolytic galvanising to powder coating, wet painting, glass bead blasting, pickling and fire-resistant coatings. This intensive collaboration enables customers to have their products treated in a single logistical movement, without any loss of time or quality.

‘We are actually a kind of supermarket for metal treatment,’ says Roel Sweegers, director-owner of Verzinkerij Meerveldhoven and De Run Metaalcoating. Together with his brother Daan, owner of Dameco Plating, he is the driving force behind the family business. ‘With us, the customer only has to drive once for all their treatments.’

Sustainability inside and out

What sets the centre apart within the industry is its long-term vision on sustainability. As early as 2009, the brothers discussed the need to go green. Sustainability was not yet a trend, but they realised early on that an energy-intensive production process was not future-proof. ‘We felt we had to transform to an environmentally friendly way of producing,’ explains Daan.

They started with solar panels. This was followed by combined heat and power units, batteries and smart energy management systems. ‘We use our own generated electricity as much as possible,’ says business controller Bobby de Meulder, who has been responsible for Finance, HR and IT within the company for several years. ‘And the energy we purchase is green.’

Parts of the production process now run entirely on solar energy. Recently, an important step was taken by replacing one of the largest gas ovens with an electric zinc oven. ‘You can compare the system to a large toaster,’ he explains, ‘where the coils heat the zinc. Previously, this was done with gas, but the electric version is much more efficient and has much less heat loss.’

Significant impact, visible results

The figures speak for themselves. These changes have reduced annual gas consumption from 1.8 million cubic metres to 800,000. CO2 emissions have been cut by almost 2,000 tonnes per year. ‘That's huge,’ says Roel. ‘And we're proud of it.’

But there are limits to sustainability. Grid congestion and the contracted capacity for electricity are creating a bottleneck. This is frustrating, especially for a company that is willing to invest and has already prepared the infrastructure. In order to make progress nonetheless, two 200 kW batteries were recently installed. ‘This allows us to absorb peaks and avoid feeding back into the grid,’ adds Daan.

Hybrid solutions and local networks

In order to use the available capacity more intelligently, new machines are designed to be hybrid as standard. ‘We want to be able to run on electricity when the grid can handle it, and on gas when necessary,’ says Bobby. A fully automated system is in the pipeline, but it takes time and careful coordination. ‘We look at every investment through the lens of energy management.’

The Centre for Sustainability also looks explicitly beyond its own walls. Together with other companies on the business park, it is looking into mutual energy exchange. ‘At the weekend, we sometimes have a surplus of solar energy, while our neighbours could really use it,’ explains Bobby. ‘We are also exploring creative collaborations. For example, with local farmers in the region who produce biogas. They can supply us with gas and we galvanise their stables. This keeps it local, circular and sustainable.’

The strength of the region

Thanks to its location in the Brainport region, the Centre benefits from short lines of communication with high-tech customers, access to innovation-oriented networks and collaboration with knowledge institutions. ‘We are literally surrounded by pioneers,’ says Roel. ‘That inspires us and obliges us.’

At the same time, it is striking that this innovative region in particular now seems to be overlooked in the national hydrogen infrastructure. As a member of the region's hydrogen leadership group, the Centre is investigating the role of hydrogen in their future energy supply. ‘The Brainport region is in danger of being left out of the major hydrogen pipelines because the national route deviates at Boxtel. Yet this region has a great need and capacity,’ says Roel. Together with other large consumers, they are now investigating whether a branch line is possible.

Despite the frustrations, the entrepreneurs remain positive and solution-oriented. ‘We have the knowledge, the network and the willingness to invest. Now we just need the space,’ says Roel. ‘It would be a shame if slow decision-making slowed us down, when we are already technically ready.’

‘If we had free rein, we would already be CO2-neutral.’

Circular applications and reuse

The surface treatments carried out by the three companies fit seamlessly within a circular economy. ‘Galvanised steel can be reused time and time again,’ explains Roel. ‘A car park frame treated by us has already been rebuilt four times at new locations. Our treatment makes this possible.’

New projects are also building on this principle. Architects are increasingly designing with reuse in mind. ‘We see customers bringing their materials back to us after years for a second or third cycle,’ says Daan. ‘That's a huge gain in terms of footprint.’

There are also striking examples of circular construction in the region. An entrepreneur bought an entire industrial building from Groningen, which is being rebuilt here using mostly existing, hot-dip galvanised materials that are still in excellent condition. ‘Thanks to the long service life of galvanised steel, re-treatment is not even necessary for the time being,’ says Bobby.

Ambition, frustration and hope

The entrepreneurs want to become more sustainable, preferably today. The municipality of Veldhoven wants to redevelop the area in the long term. New homes will be built, functions will change and companies may have to relocate.

‘That's all well and good, but it's quite difficult for us. We are simultaneously optimising this location and thinking about where we can go next,’ says Bobby. For the time being, they are staying here and making use of every square metre. ‘But the slowness of decision-making is slowing us down,’ says Daan. ‘If we had free rein, we would already be CO2 neutral.’

Still, there is hope. Contacts with network operators are improving, batteries are being tested and cooperation in the region is growing. ‘There is enough power in theory,’ says Roel. ‘But it's currently tied up in contracts. It would help if unused capacity could be redistributed.’

So they carry on. Every installation and every investment is assessed in terms of energy consumption, reusability and impact. Not because they have to, but because they believe it is the right thing to do. Especially in a region that is at the forefront of technology.

‘We believe this is the only right way forward,’ concludes Daan. ‘We do this for ourselves, for our customers and for future generations.’