The story of MUSA: the best microsurgical robot in the world

During the ten-day Pioneers in Medtech series, we feature stories about start-ups, suppliers and scientists working on the Microsure MedTech of the future. In this instalment: Sjaak Deckers, CEO of the MedTech company Microsure.

Microsure, based in the Dutch city of Eindhoven, develops robotic platforms for microsurgical operations. The company has been around for six years now and has since grown into a mature business. It all started in the laboratory at the Eindhoven University of Technology (TU/e), where professor Maarten Steinbuch was asked by a number of plastic surgeons from the Maastricht University Medical Centre to develop a robot.

Microsurgeons suture very fine blood vessels and sections of the body. This work is so fine that it is on the verge of being inhuman, Deckers explains. "Tiny blood vessels can have a diameter of half a millimeter or even smaller. In order to join two veins together, a microsurgeon must make at least four or five sutures in a blood vessel that they can barely see. Whenever a child comes to the emergency room with a severed finger, that finger often ends up being amputated. Basically, because it takes too much time and effort and there are not enough doctors who can perform such an operation."

MUSA-1 and 2

Steinbuch and his PhD student Raimondo Cau began developing a prototype (MUSA-1) that should make these kinds of surgeries easier. This succeeded so well that back in 2016, TU/e said: turn it into a company. And so, start-up Microsure was born, where they continue to work on a robot that can be launched on the market.

Changing tack

When Deckers took office two years ago, it became clear that MUSA-2 was not yet a mature product. After a period of intensive use, it needs too many repairs and tests, and it does not yet meet all the criteria set by doctors. Deckers sees this more often in spin-offs from universities: they have exceptional knowledge, but not enough industrial experience. The CEO, together with management, then decided to change tack and develop a new, improved version. "That decision came as a huge shock to the company and investors, but now everyone is happy about it."

For Deckers, who earned his doctorate in physics, this was not the first time he had to make this type of far-reaching decision. At Philips, for example, he was involved in a start-up for flat panel X-ray detectors, which has now grown into the largest company of its kind. He also founded two companies of his own: Sapiens, which was sold to Medtronic in 2014, and GTX Medical (now Onward Medical), which is now listed on the Amsterdam and Brussels Euronext exchange.

MUSA-3: an extensive list of criteria

In order to develop a robot that can be launched on the market, Microsure's clinical team is talking to a large number of doctors. These discussions have resulted in a list of additional criteria. For example, the equipment has to be mounted on a trolley so that it is easy to install, it has to be able to cover a sufficiently large operating area and it has to be able to move around freely. And: when there is a power failure, the robotic arms must not fall down (onto the patient), but freeze in position.

"Next, our development team, which is made up of mechanics, electronic engineers, software developers and control engineers, translates those criteria into concepts. Those concepts are tested and fine-tuned. Now we are in the final phase where we integrate all those separate parts and test whether they also collectively meet the requirements of clinicians," Deckers says.

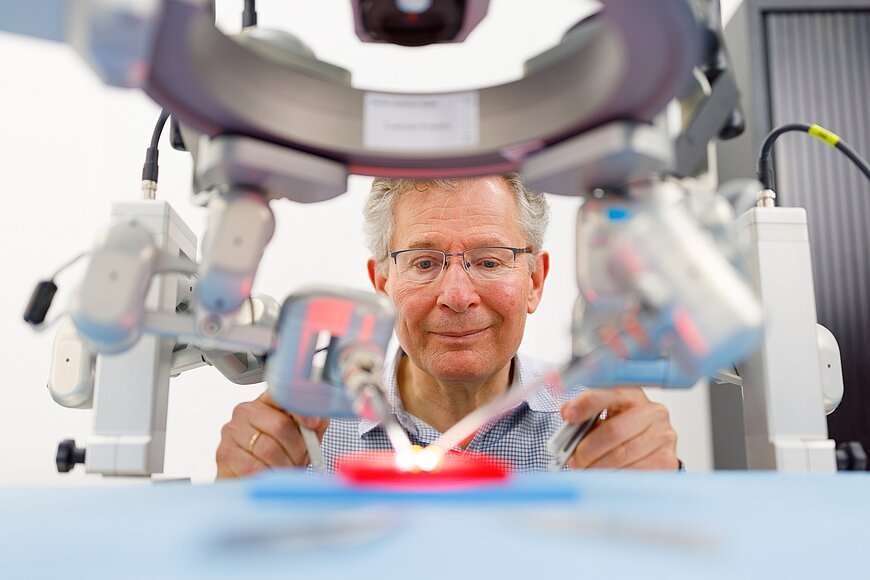

All those criteria have come together in the MUSA-3 robot. You can visualize how it is used as follows: A surgeon controls two joysticks in the shape of tweezers from behind a table. The surgeon then looks through 3D glasses at a large screen that is connected to a digital microscope hanging above the patient. The movements the doctor makes with the joysticks are detected and translated into movements of the instruments on the robotic arms. Those movements can be scaled down as much as twenty times, and any vibrations from the doctor's hands are filtered out. At the ends of the robotic arms, surgeons can attach various micro-instruments - tweezers, needle forceps or scissors.