Eterna, the car that promises to last a lifetime thanks to a modular upper and lower section

The bottom part of Eterna contains the long-life systems. The shorter-life systems come on the modular top at the top.

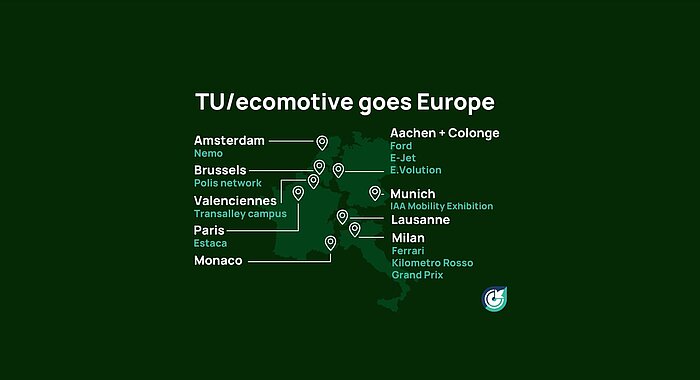

After Penny, Isa, Nova, Lina, Noah, Luca, and Zem, it is the turn of Eterna, “the eternal one.” Team TU/ecomotive‘s newest car is ready for its traditional tour of Europe. The unique feature of the Eterna lies in its modular construction: the lower part contains long-life systems such as the drive train, batteries, and steering system. On top of that come the designs with a shorter lifespan or with necessary interim updates, such as sensors, cameras, and upholstery. This way, the top can be continuously updated while the undercarriage lasts much longer. Overall, the result is a “car that lasts a lifetime.”

“In the past ten years, TU/ecomotive has gone from a simple energy-efficient car to one of the most ambitious sustainable concept cars of our time with ZEM, the car that captures CO2,” says business manager Hugo van Hees on the website of sponsor Apex Dynamics. “Now, we are busy with the next step in our process. Not just by continuing where previous generations stopped but with a vision of the future in which climate-positive mobility is accessible to everyone.”

Electrification of mobility brings us closer to a climate-neutral future. But, says Van Hees, “electrification also raises many new problems. Most emissions come from materials production in a world that runs on electric mobility and where the energy mix is green. This could even reach 60% of total car emissions by 2040.” According to TU/ecomotive, the solution lies in extending the car’s life cycle. “If instead of driving this car for 100,000 km, you would drive it for 200,000 km, you can halve the emissions per kilometer. So driving longer pays off!”

Life cycles are pulled apart

Electric cars require very little maintenance, especially compared to internal combustion engines. Batteries also last longer and longer. At the same time, parts within the car’s interior wear or damage a lot faster, and safety systems such as cameras and sensors constantly require new versions and features. Van Hees: “This creates a relatively large gap between the lifespans of different components, and that’s exactly what our idea addresses.”

By pulling apart the different life cycles, you handle the whole thing more carefully and sustainably, is the idea. The bottom part, “the modular board,” contains long-life systems such as the drive train, batteries, and steering system. The shorter-life systems then come on the modular top at the top. “Instead of replacing the entire car, you can replace only the top portion of your car. This provides a big reduction in material production.”

"Instead of replacing the entire car, you can replace only the top portion of your car. This provides a big reduction in material production."

Business manager Hugo van Hees

Taiwanese

For the concept to succeed, the bottom of the car must last a very long time. “Then you don’t use Chinese parts, but Taiwanese, of course!” Not coincidentally, Apex Dynamics’ factory is located in Taiwan. This means everything that moves must have minimal play to maximize longevity. “The car needed a gear ratio of 1:6 to ensure that the output torque of the driveline was sufficient to drive the car.”

The Eterna uses rear-wheel drive with two motors, one per driven wheel, which limits the space for a transmission. “That’s why we looked for a planetary gearbox because they are very compact. And because the motor will not run at high speeds, this opened up the possibility for Apex Dynamics’ AE series. The AE090 was compact enough to fit in the available space, had the right gear ratio, and was relatively lightweight. Two AE090 gearboxes are now used in Eterna, one for each motor, and they are attached to the motor via a mounting plate also supplied by Apex Dynamics.”

Move Forward

At Apex, the management was happy to supply the two gearboxes with the mounting plate. “Apex Dynamics wants to move the world forward,” says Managing Director Thom van Oss. “That’s also why our slogan is ‘Move Forward.’ Supporting student initiatives is an important part of that. They come up with solutions to tomorrow’s issues, and with our support, we enthuse young people about technology. So it goes together perfectly. TU/ecomotive’s project ties in well with that.”