Uranium-free medical isotopes are a breakthrough in nuclear medicine

Belgium's IRE, ASML and the technology company Demcon have completed a successful trial involving the creation of medical isotopes based on accelerator technology.

The supply of medical isotopes is becoming increasingly more problematic. There are only six reactors in the world that are responsible for producing them. At the moment, the power plant in the Dutch town of Petten is shut down on account of leakages in the cooling system. This means that cancer patients run the risk of having to wait longer for a diagnosis or therapy while their health deteriorates.

Highly enriched uranium

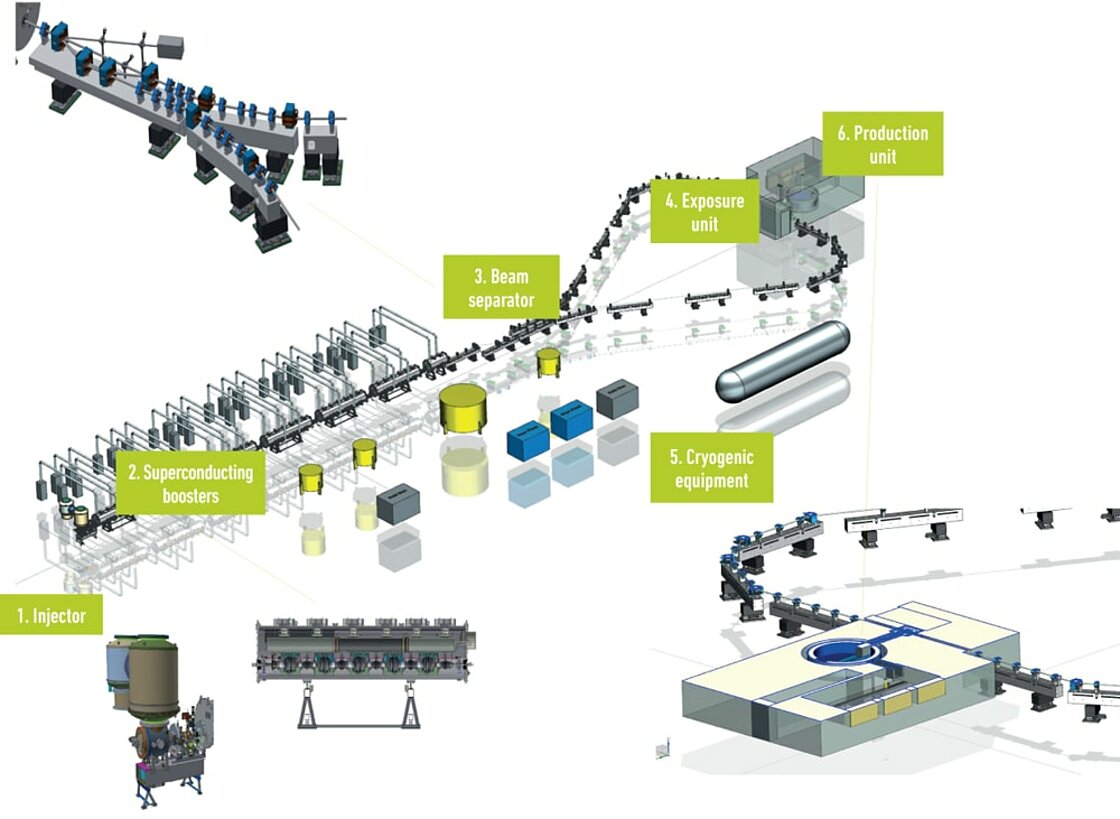

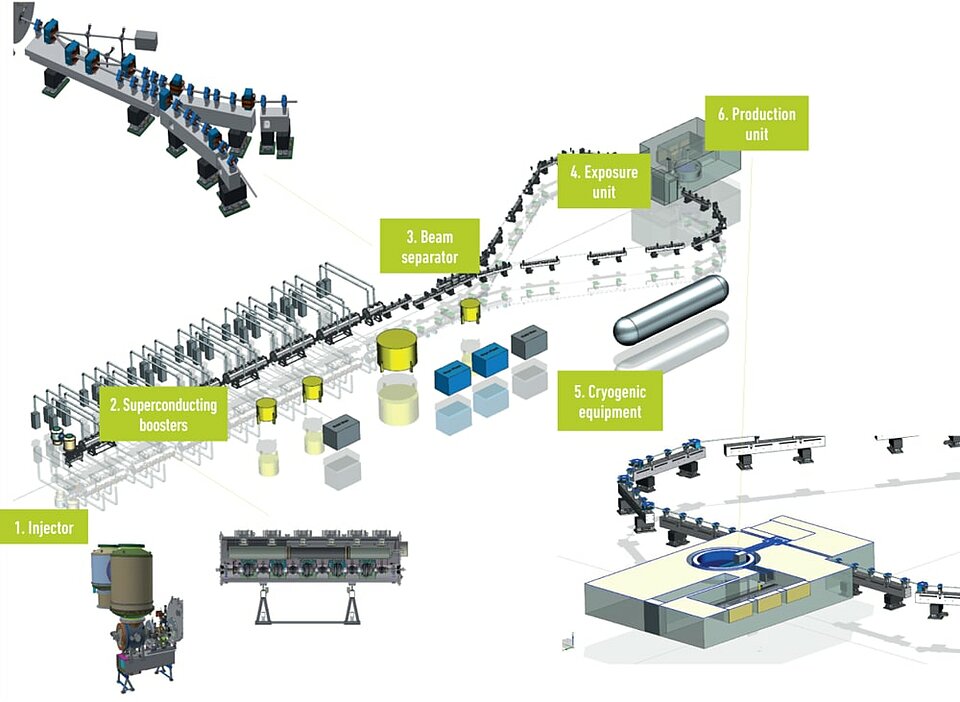

To avoid having to rely on specialized, mostly outdated nuclear reactors, the Belgian Institute of Radio Elements (IRE) launched what is known as the SMART project (Source of MedicAl RadioisoTopes) back in 2015. This project aims to develop a sustainable and reliable alternative that is based on a technology accelerator and which does not use uranium. Developing an alternative to highly enriched uranium would also be preferable from an environmental and safety point of view. ASML became a participant in the project in 2018. Another partner is Demcon, a Dutch developer and producer of technology.

Under the SMART concept, 99Mo is derived in a different way than is usually the case for applications in nuclear medicine. 99Mo is an isotope that is the raw material for the production of technetium-99m. This 99mTc is used as a radioactive tracer in nuclear medicine. This means that it is important for research into a wide range of diseases.

Electron accelerators

In the case of SMART, the non-radioactive molybdenum-100 (100Mo) is irradiated with an intense beam made up of accelerated electrons. Compared to conventional nuclear reactor production, this alternative does not require enriched uranium and produces virtually no ‘long-living’ radioactive waste. But the current electron accelerators that have been used in this field so far do not meet the specifications for large-scale production of 99mTc.

In a trial conducted earlier this month (which was only disclosed this week), ASML was able to produce a superconductive, high-performance linear electron accelerator. The accelerator fires high-energy electrons at the target that’s made up of 100Mo-enriched molybdenum, which is then converted to 99Mo. This device from ASML is a free-electron laser system which is based on electron accelerator technology.

The test entailed cooling with liquid metal under extreme conditions. The experiment set a world record for the highest continuous power density ever withstood by a man-made object. The target was designed by Demcon to survive the extreme heat load that the electrons inject. “In order to be compatible with today’s generator technology, the initial activation level needs to be high enough,” says Johannes Jobst, senior mechatronic systems engineer at Demcon.

Crucial milestone

“This level of activation necessitates focusing the beam on a target no bigger than a matchbox. Without intense cooling, the target would evaporate instantaneously. Only liquid metal provides enough cooling power, due to a highly specific heat capacity and conductivity. After some research, liquid sodium proved to be the best coolant for the SMART plant.”

The successful test is a crucial milestone towards an eventual commissioning of a SMART plant. According to a project presentation by IRE, the first pilot plant should be up and running in 2024. Commercial production could start in 2026.