Europe’s once-in-a-lifetime chance to reduce emissions in computer technology

The semiconductor industry is like an ultimate Champions League. A handful of strong teams, acquiring the best players of the world to play the best games and reach that glorious cup. And every year, the expectations when it comes to performance levels get ever higher. I admit that sometimes the matches are not that interesting, but when they play well, it’s a joy to watch.

I guess similar to human performance limitations, and in view of Moore’s law, semiconductors will also inevitably reach their limits. But so far it seems that the semiconductor industry is high on taurine and progress is beyond expectations. This week at TSMC Technology Symposium, TSMC updated the industry on their on-track progress, +1 Billion 7nm chips shipped, N6 performing at the same level of N7, N5 Volume production, and N3 development on track.

Hot chips and nodes

Just some clarification on the nodes, as Philip Wong explained in his Hot Chips 31 keynote speech: “It used to be the technology node, the node number, means something, some features on the wafer. […] Today, these figures are just numbers. They’re like models in a car – it’s like a BMW 5-series or Mazda 6. It doesn’t matter what the number is, it’s just a designation of the next technology, the name for it. So, let’s not confuse ourselves with the name of the node with what the technology actually offers.”

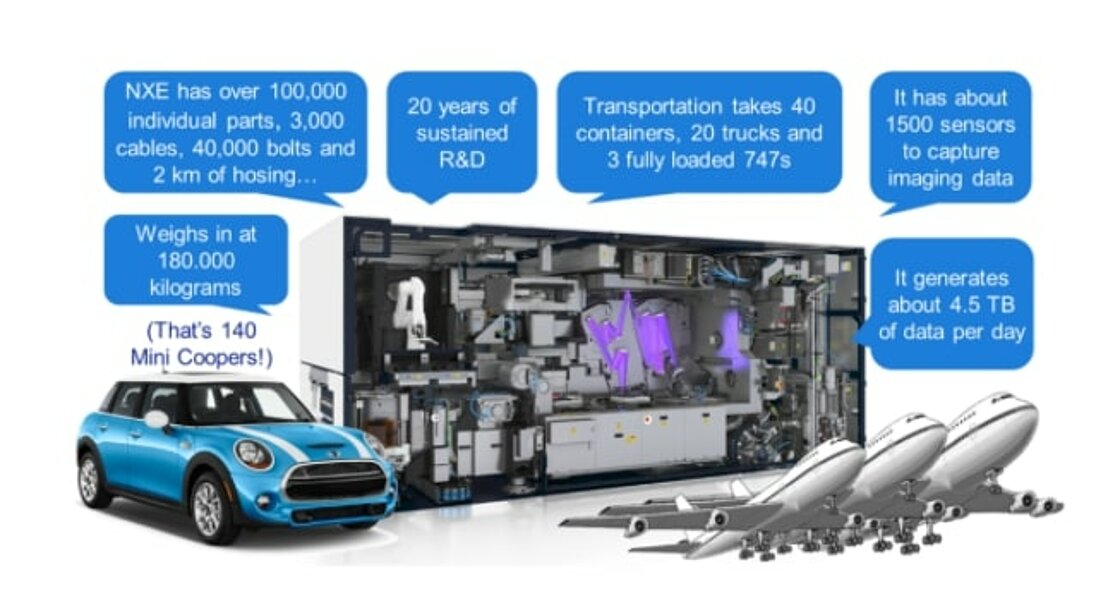

These are said to be able to build chips in N7, N5, and N3, where EUV light with a wavelength of 13.5nm is used. The precision needed to achieve high-volume manufacturing is like flying an airplane with centimeter-level accuracy inside a tunnel.

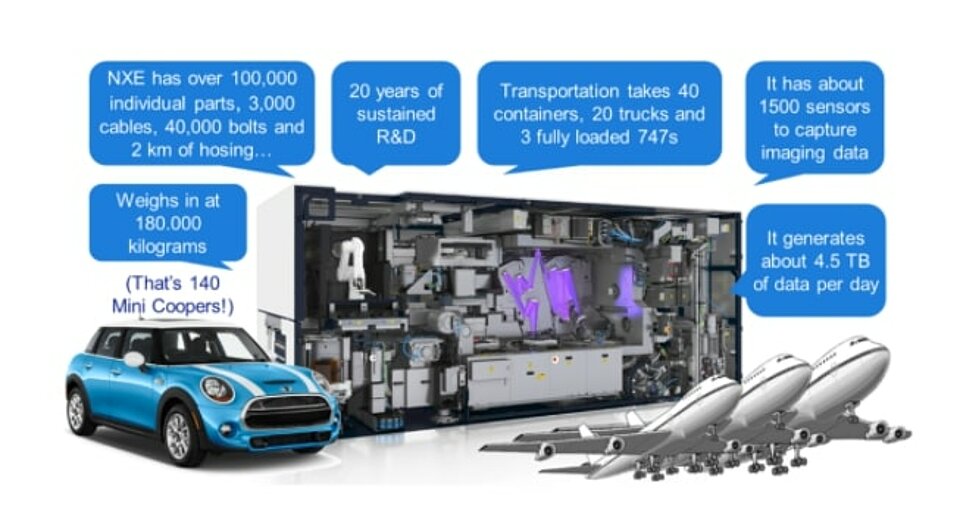

The underlying tool that enables this leap in the semiconductor industry is nothing less than the EUV machinery. A very complex machine that has more than 100K individual parts and weighs about 180 metric tons. But let’s not forget that it has been a collective effort for 20 odd years of R&D and innovation at ASML together with its customers. Or perhaps more appropriately, its partners like TSMC and also Samsung and Intel.

Smaller and smaller while demand grows bigger and bigger

Digitalization, especially in sectors like Automotive and IoT is progressing at an ever-increasing rate. This will lead to a sustained and long-term demand for high-, mid-and low-end semiconductor chips. As the chips are getting smaller and more efficient, the industry is facing a paradox.

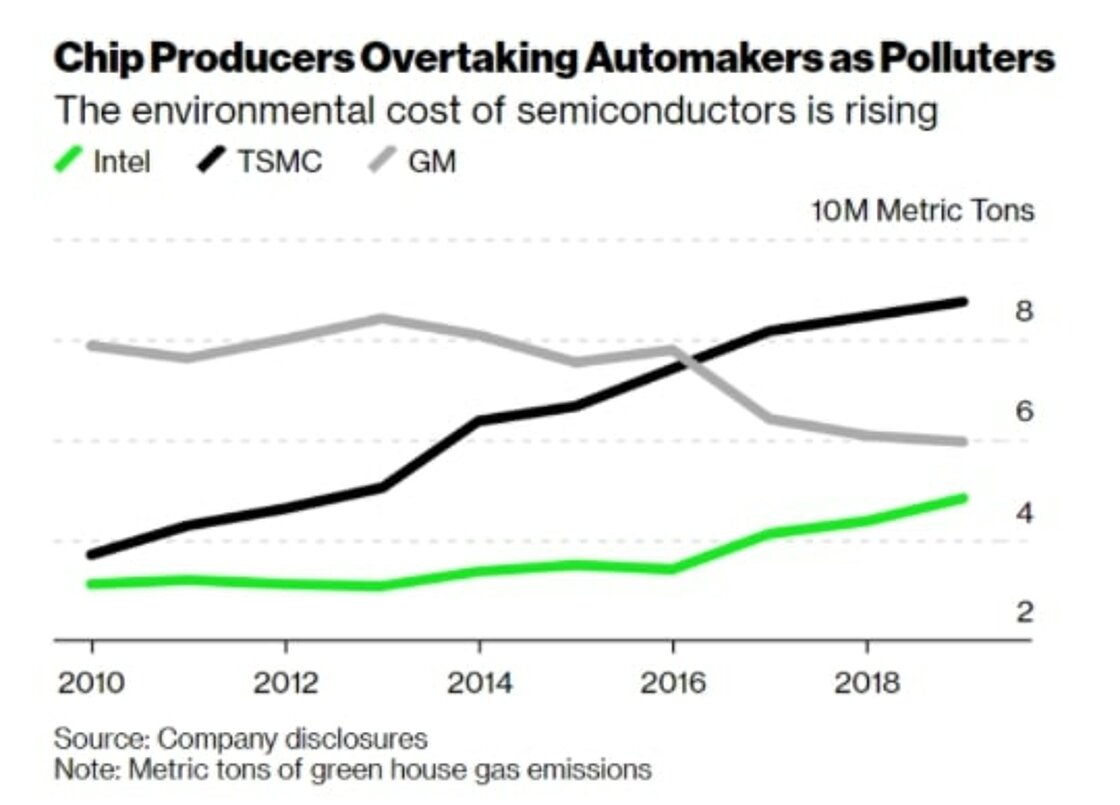

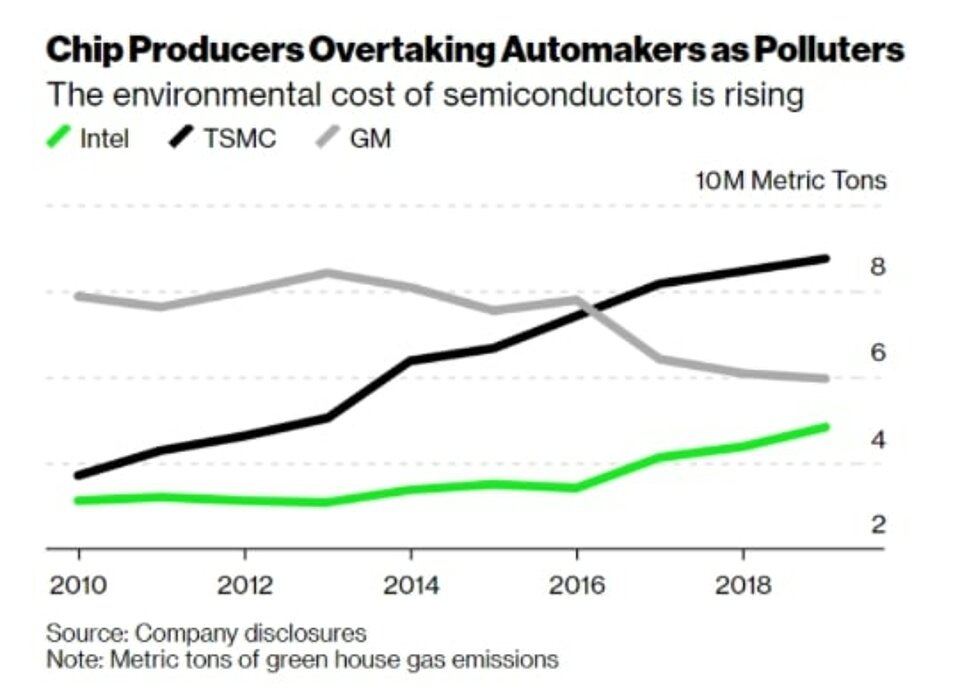

In the fight for increasing capacity and supply and demand, one thing that gets less attention is the environmental impact of the industry. For more than a decade, researchers are working on ways to measure the CO2 footprint for semiconductor products. However, it is still hard to link semiconductor fabs and our digital devices to CO2 emission. Just as it is for chemical or petroleum factories or cars that have exhaust pipes attached to them. With the rise in production capacity of advanced nodes, the power and water consumption of these fans and re-use/recycling of semiconductor chips and digital devices have now become serious issues.

Global energy demand

Computing technology is predicted to account for as much as 20% of the global energy demand by 2030, with hardware responsible for more of that footprint than the operation of a system. This means that: chip manufacturing, as opposed to hardware use and energy consumption accounts for most of the carbon output. In addition to that, chip manufacturing also requires a huge amount of water to cool machines in fabs. In 2019, the latest year for which data is available, TSMC’s daily water consumption in Taiwan was 156,000 metric tons per day. At its northern production sites, the company accounted for 10.3% of that region’s daily supply.

This is not something to ignore or be frightened of. With the advent of ESG, environmental, social, and corporate governance, chipmakers are being forced to take action and the major chip makers are working to address their emissions. Now that Europe is seriously discussing the option of a leading-edge fab, the CO2 footprint and other ESG aspects should be included in the master plan. Let’s not dismiss this once-in-a-lifetime chance!