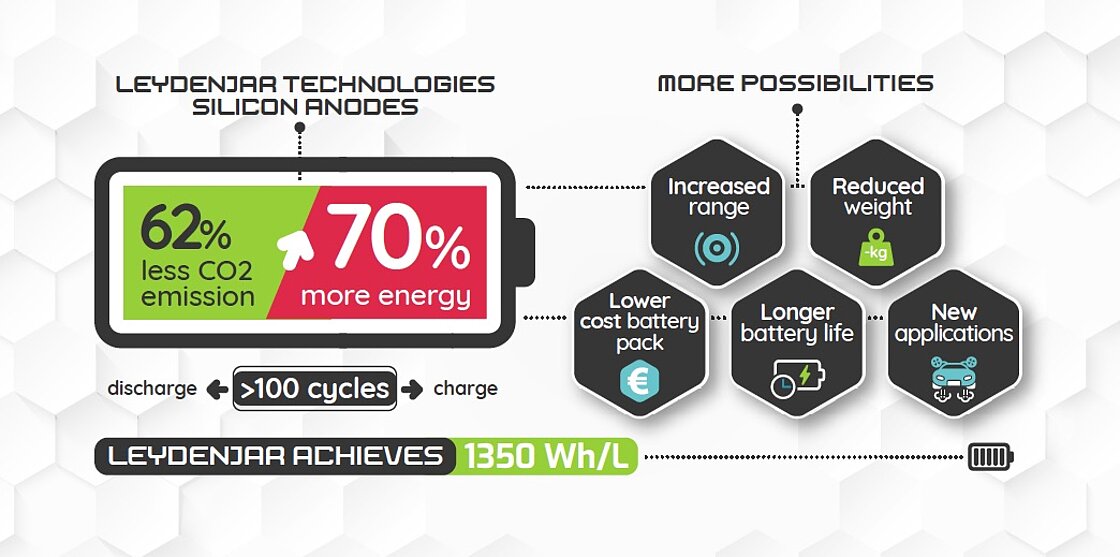

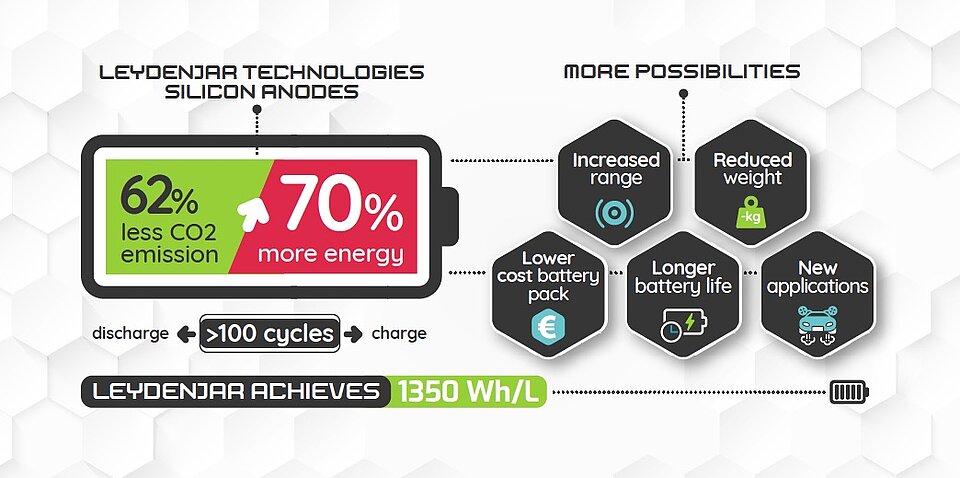

Breakthrough in battery industry: LeydenJar boosts battery energy by 70%

LeydenJar Technologies, a Dutch spin-out of the applied research institute TNO, has developed a new anode that will drastically change the battery industry. For the first time, anodes in lithium-ion batteries can be made from 100% silicon. This breakthrough offers two key benefits: batteries with a 70% higher energy density (1350 Wh/L) and 62% less CO2 emissions. The anode is ready for production and LeydenJar is preparing to massively scale-up its production capacity in the coming years.

Impact on innovations

Battery performance determines the pace of innovations in many tech sectors. This hugely significant innovation, focused on the silicon anode, can accelerate this process in the short term. Two important details are that the new technology does not push up production costs and is a ‘plug-in’ solution to existing battery gigafactory’s. A 70% higher energy density will have an impact on various sectors: consumer electronics, electric vehicles and the storage of renewable energy.

Pure silicon replaces carbon

So far, it has only been possible to produce anodes with a small amount of silicon, because they were mainly carbon based. As an anode material, silicon has ten times the capacity of carbon. Until now, the use of silicon was hampered by the mechanical limitations of the material. LeydenJar’s technology is derived from solar cell production technology (plasma-enhanced chemical vapour deposition, or PECVD).

Founder and managing director Christian Rood: ‘The significance of battery capacity is huge. Electric driving, more intelligent smartphones, electric flying… everything and everyone is waiting for better batteries. Our solution is smart and easily incorporated. And there’s no additional cost. We cordially invite everyone to use and experience the advantages of LeydenJar’s silicon anodes.’