An electrolyzer the size of a washing machine, to store local solar power in every home

EIRES wants to design electrolyzers that can be placed in your home to store electricity generated by solar panels or wind turbines.

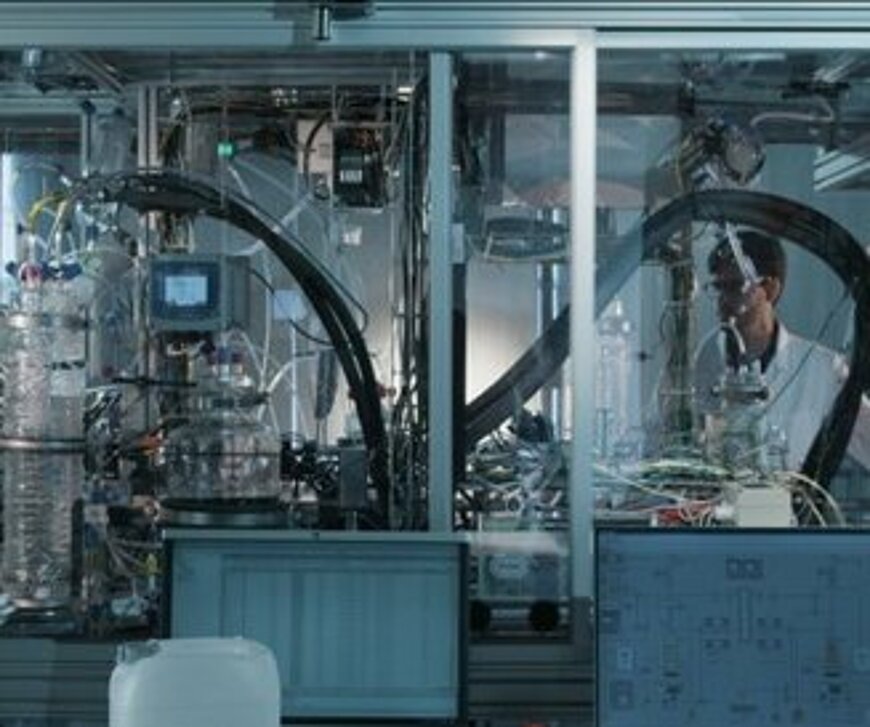

The Dutch Electrolyzer is one of the four iconic projects of the Eindhoven Institute for Renewable Energy Systems (EIRES). The ambition is to design and engineer in the near future electrolyzers that you can place in your home to store electricity generated by solar panels or wind turbines, for example. In this way, households always have access to sustainable energy. Even when the sun isn’t shining or when the wind is not blowing. The intention is that it does not become larger than a washing machine and that it is part of the usual white goods inventory of every home.

H2O electrolysis and, therefore, electrolyzers, are a robust and well-known technology, says Adriana Creatore, principal scientist at EIRES in the focus area “Chemistry for Sustainable Energy Systems”. Thanks to electricity, water is literally “split” into hydrogen and oxygen. The hydrogen and oxygen are collected separately. Hydrogen is not only key to re-generate electricity by recombination with oxygen through fuel cells (for example for electric transport), but also a major building block to synthesize chemicals and fuels when combined with CO.

So the technology is just there. “The challenge is that the materials we now use for it are too expensive.” This concerns, for example, scarce precious metals and compounds such as platinum (also called white gold) and iridium oxide. The research conducted by Creatore and her colleagues at TU/e in the context of EIRES focuses on designing and engineering cost-effective materials so that they can replace expensive metals and compounds such as platinum and iridium oxide.

Fundamental research into materials

Those materials must then consist of raw materials that are more available. As examples, Creatore mentions a very appealing compound based on cobalt, phosphorus, and oxygen, named cobalt phosphate, which is a relevant electro-catalyst for the O2 production at the anode of the electrolyzer. But of course, there are many more options and, in this respect, her collaborations with the TU/e colleague Marta Costa Figueiredo and the DIFFER colleague Mihalis Tsampas are meant to exploit other options.

“We are not only interested in the synthesis of these new electro-catalysts but also in their activation mechanism during water splitting and in the performance and stability in the long term.” So that’s fundamental research.

Keeping Hydrogen technology close by

It is also essential to strengthen collaborations outside the Netherlands. Both the German and Dutch governments have the theme of electrolysis, high on the agenda for future collaboration. Both governments support further bilateral national agenda setting for future bilateral programming, says Creatore. “It is important to develop that knowledge here so that the local manufacturing industry benefits from it.”

For this reason, companies are also involved in the development of a new generation of affordable electrolyzers, such as the Eindhoven-based VDL, Nouryon, and several start-ups. It is highly essential to cover the whole chain of knowledge, says Creatore. EIRES supports this by promoting the synergy among its focus areas and specifically between “Chemistry for Sustainable Energy Systems” and “Engineering from Sustainable Energy Systems”, led by the TU/e researchers Niels Deen and John van der Schaaf, whose focus is on the engineering aspects of the electrolyzer.

The Dutch Electrolyzer is one of four iconic projects of the Eindhoven Institute for Renewable Energy Systems (EIRES). EIRES was founded by TU/e in 2020. Other projects include the development of a salt battery to store sustainably generated heat and the development of metal fuel. Digital twins are also being developed to gain insight into the best choice for new technologies that will be developed during the energy transition. The choice must be made before 2050.