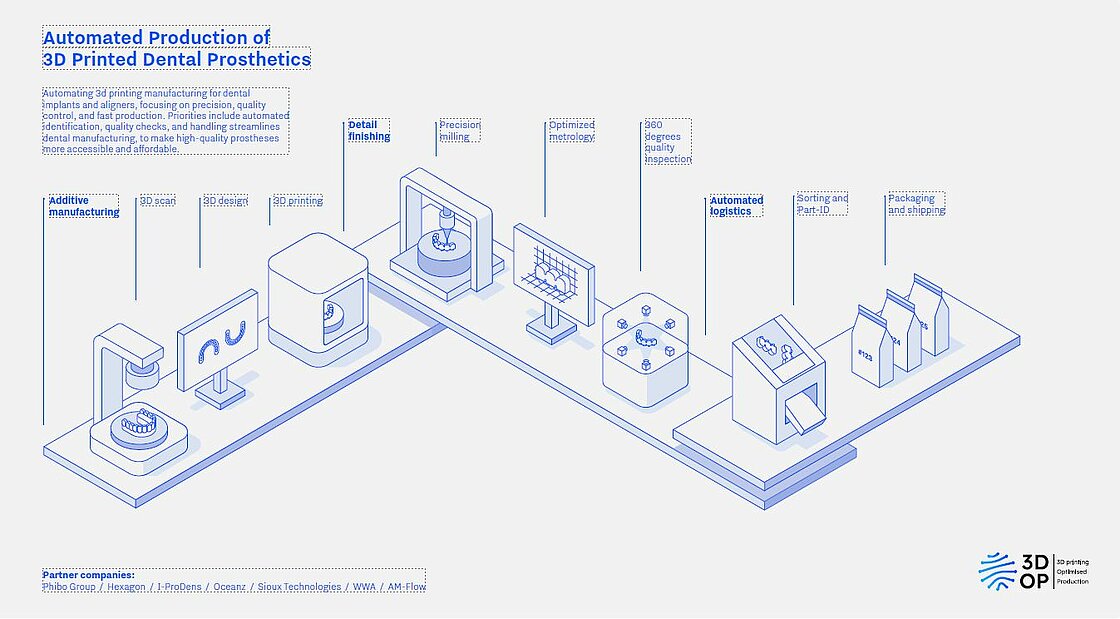

Automated Production of 3D Printed Dental Prosthetics

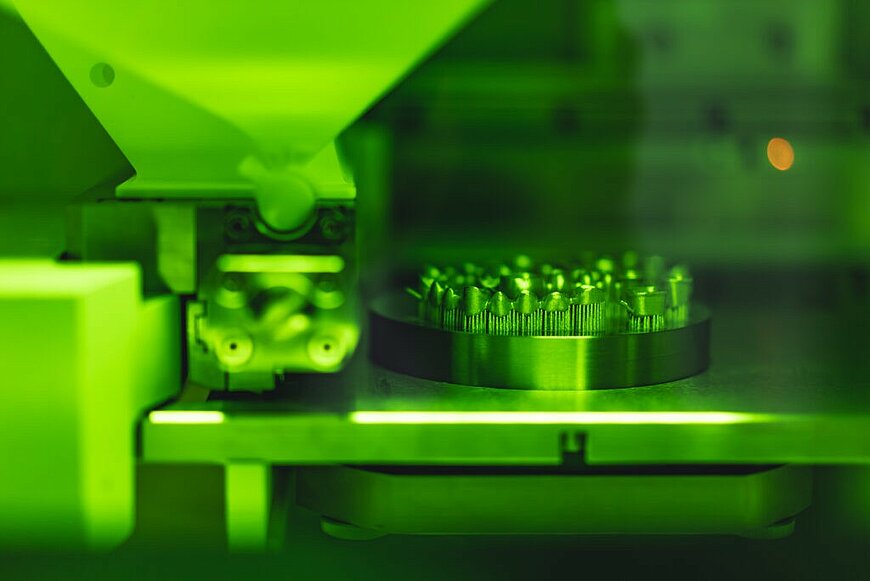

The traditional manufacturing process in the dental industry involves significant manual labor, particularly in identifying, quality-controlling, and packaging dental products, which can be time-consuming and prone to error. 3DOP seeks to automate these manual processes, thus improving efficiency, reducing costs, and increasing the speed of production. This includes automating the identification of individual dental prostheses using digital files, performing quality checks, and handling the transportation and packaging of the final products

Objectives for dental 3DP are structured around three main tasks:

1. Automated identification of dental parts, ensuring that each prosthesis can be matched to its corresponding digital file with precision.

2. Automated quality control, which involves advanced scanning techniques to detect defects, such as warping, scratches, or imperfections in the shape and color of dental parts.

3. Automated handling and transportation, using robotic systems to accurately pick and place dental prostheses in the correct packaging, streamlining the shipping process.

The project is finalizing the development of two key demonstrators: one focused on automated quality control and the other on automated handling. These demonstrators are currently being refined, with partners working on overcoming technical challenges related to the small size and complexity of dental parts. The success of these demonstrators is crucial for the project’s goal of fully integrating automation into dental manufacturing.

3DOP is transforming the dental industry, making high-quality dental prostheses more accessible and affordable while maintaining high standards of precision and speed.