3D Printed Moulds with Embedded Electronics

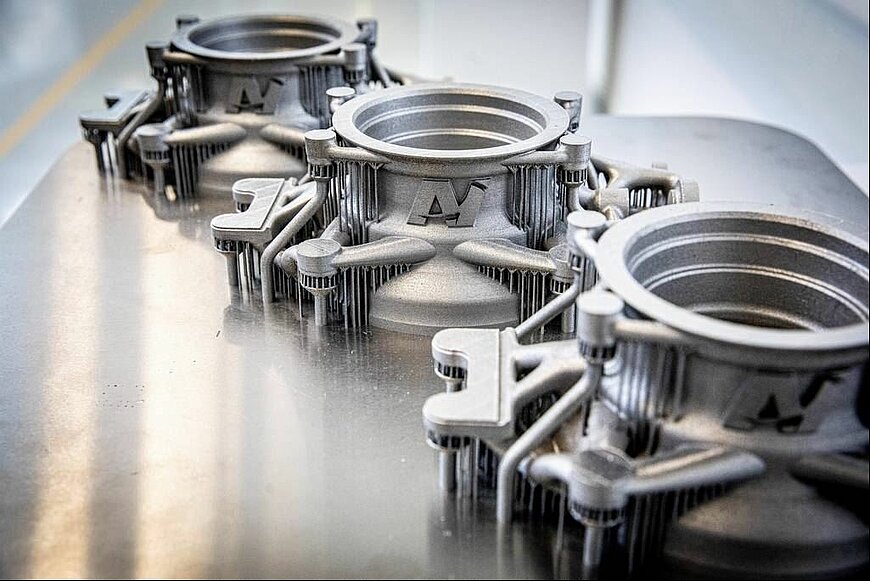

The team of companies' approach involves embedding sensors and electronic circuits directly into 3D-printed moulds. This innovation allows for real-time monitoring of production conditions, enabling operators to make adjustments and improve product quality. The embedded sensors can detect issues like temperature fluctuations or mechanical stress, leading to more consistent and reliable manufacturing outcomes.

The work package also highlights collaboration with partners in industries such as lighting and the automotive sector. For instance, partners are working on developing 3D-printed lamps with integrated sensors for the lighting industry and lightweight components for the caravanning and nautical sectors. These innovations are designed to increase efficiency, reduce material use, and support sustainable manufacturing practices.

WP3's efforts are also directed towards expanding the adoption of these technologies across Europe by implementing pilot plants in multiple locations. These pilot plants aim to demonstrate the effectiveness of 3D-printed moulds with imprinted electronics, making the technology accessible to both developed and less technologically advanced regions.

This part of 3DOP places significant emphasis on building value chains with partners of various sizes, from startups to established industry giants. The aim is to foster a collaborative environment that accelerates the development and adoption of innovative manufacturing techniques. This collaborative approach ensures that knowledge and technology developed within the project can be widely shared, promoting innovation and growth in diverse sectors.