PowerNEST uses the power of wind and solar for energy-neutral high-rise buildings

Together with a chain of suppliers that is almost entirely concentrated in Brainport Eindhoven, scale-up IBIS Power makes energy solutions that use the power of the sun and the wind. The company develops gigantic steel constructions that consist of wind turbines and a roof of double-sided solar panels. These so-called PowerNESTs are placed on high-rise buildings and make use of the forces of nature and the entire roof surface. In this way the constructions contribute to decentralized natural energy generation. High-rise buildings in the Netherlands and beyond can benefit from this innovation from Brainport Eindhoven.

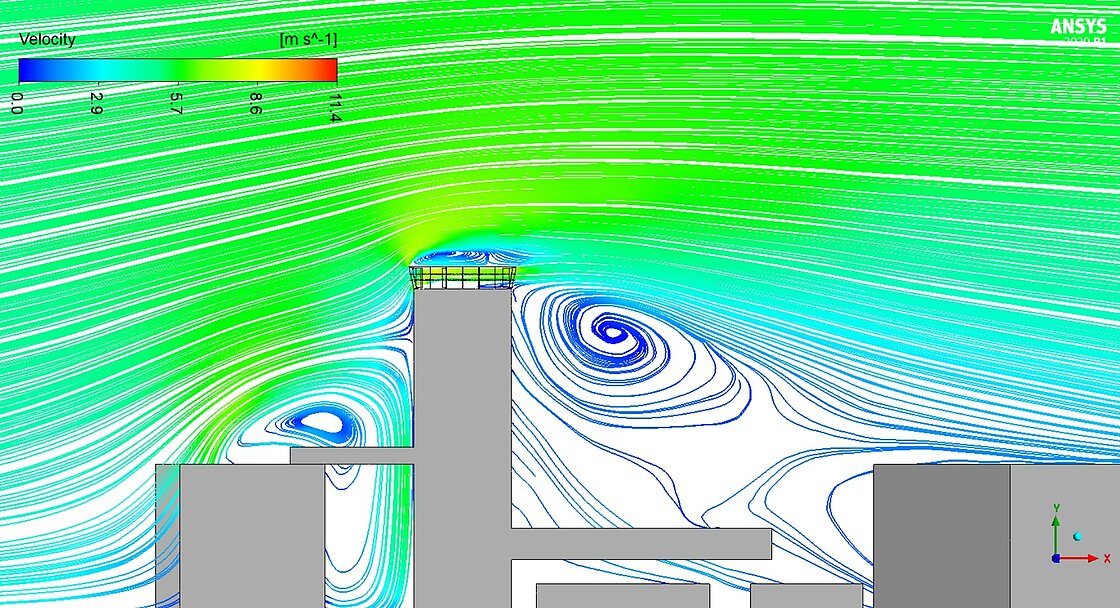

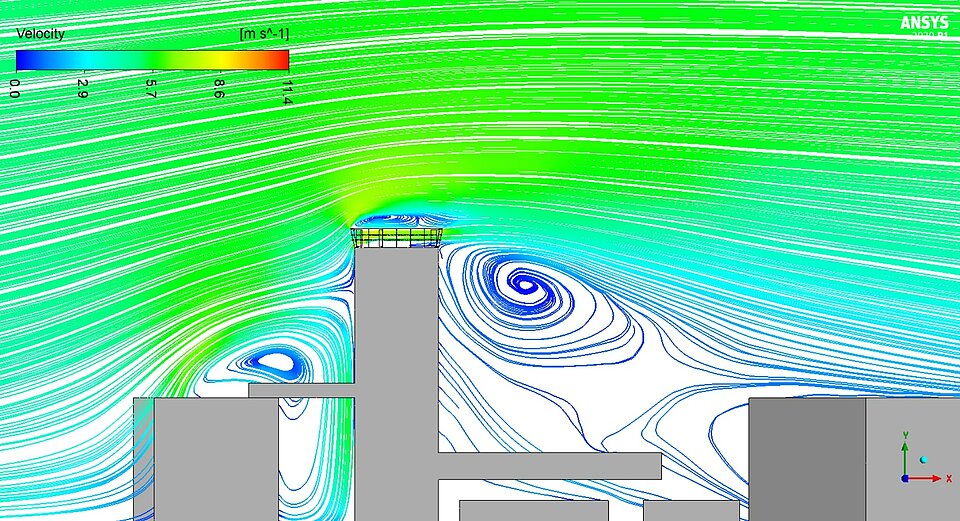

“Our PowerNESTs are steel constructions in which wind turbines and bifacial solar panels are integrated,” says Chief Operating Officer at IBIS Power Ben de Laat. “The bottom of the construction is white so that it reflects light. Through the combination of factors, we make optimal use of natural energy sources. The sun is not always very strong, but it is almost always windy at a height. In addition, our constructions are placed on buildings of at least five floors and we make use of the so-called Venturi effect. This means that the wind is captured into the construction. As a result, we always generate energy.”

Significantly higher efficiency solar panels

“With our construction we use the entire roof surface as we can place it over obstacles such as air conditioning units. The solar panels are cooled by the wind, which gives them a higher yield. As a result, we can generate almost six times as much energy than comparable roofs that are only equipped with conventional solar panels. The noise the wind turbines make is very limited. It has a maximum of 40 dB and it hardly causes any vibrations. When there is a storm, the wind turbines stop automatically.”

Several PowerNESTs are a reality

“The first version of the PowerNEST was placed in Utrecht in 2017. That was a prototype. Since then we have realized various projects, including in Utrecht, Rotterdam and Katwijk. Our project in the Eden District in Rotterdam on the Maas will be completed at the end of March and we will also equip two buildings with a PowerNEST at Strijp-S in Eindhoven. The energy revenues vary per project. A PowerNEST near the coast delivers about 30 megawatts per year and more inland about 20 megawatts. The yield of solar panels is more or less the same; the yield from wind energy differs.”

Increased demand for innovative energy solutions

“We notice that the demand for the kind of innovative energy solutions that we offer is increasing. On January 1st 2021, a new regulation was introduced called BENG, which stands for nearly energy-neutral buildings. This means that buildings must generate 50% of their electrical energy from renewable sources near or on top of the building. It is all about generating energy locally. You want to realize this as close to the customers as possible to avoid unnecessary infrastructure. In addition to the fact that our product revolves around renewable energy and sustainability, we are also critical when it comes to the sustainability of our production process and our carbon footprint.”

Most suppliers concentrated in Brainport Eindhoven

“Both for the development as the production of our PowerNESTs, it is an absolute advantage to be in Brainport Eindhoven. Most of our suppliers come from the region. They have a very specific expertise and they actively think along with us in development and production. Take Kuijpers Metal technology from Reusel, this company makes the mounting plates of our louvres. Kuijpers is skilled in making complex shapes. The shape of the louvres is essential for the Venturi-effect. We designed the shape of the mounting plate together with Kuijpers, as well as the angle of the louvres and the width. The plating at the bottom and top is made by Plano Plastics in Veldhoven. Those plates are shaped aerodynamically otherwise the wind will hit them. We also approached them because of their expertise. The production of the steel construction and the installation ‘on site’ is done by GS Staalwerken from Helmond.”

“We also have a good relationship with Eindhoven University of Technology (TU/e) and we work closely with TU/e in the further development of the product. Brainport Development has also actively helped us in our growth process from start-up to scale-up. Finally, we are looking for a connection with Brainport Industries to see whether we can produce our product in a smarter way by using advanced ‘Smart Manufacturing’ technologies.”

Modular elements in combination with custom engineering

“Our constructions are modular, but the engineering is customised. Our solutions are fully tailored to the buildings on which they are placed. In the case of new building, we can already take into account what is needed for the installation of a PowerNEST during the construction. When it comes to existing buildings, we look at what is needed to make the PowerNEST suitable for the building. Our solution is also tailor-made from an aesthetic point of view, we ensure that the design matches the architecture of the building. In addition, you can integrate the facade maintenance requirements into the PowerNEST.”

Expansion in Europe and US and realizing the ‘factory of the future’

“What we need to make PowerNEST an absolute success are good people and investors. I have commitment from the government, but it is still difficult to find market parties when it comes to cleantech and energy hardware. Our ambitions are to conquer the European market in the coming years and to take the first steps in the US. In addition, we want to build a pilot plant or factory of the future in Brainport in which we apply advanced manufacturing technology to develop ourselves into a mature organization.”