Not AI but domain knowledge is what sets you apart from the rest

Why should you invest in AI now? Both the expected ROI and risks are still highly insecure. Nevertheless, ASML invests heavily in applying AI. The company is not only one of world’s most successful high-tech companies and world-leader in making lithography machines but also a true leader in AI. Arnaud Hubaux (ASML), senior technical program manager AI, shares his lessons learned. His key take-away during a lecture at the AI Leadership Forum: AI on its own is not a Unique Selling Point but a commodity. Defining your use cases and applying AI in a smart way is what sets you apart from the rest. Your domain knowledge is what distinguishes you from your competitors.

“Much is still unknown when it comes to AI, “says Arnaud Hubaux during a session organized by AI Innovation Center. “A lot of leaders in companies around me wonder if they should invest in AI. Reports promise the moon, but a lot is still unknown and the expected Return On Investment is still insecure. So why should you get on this train now?”

Keep the end-customer in mind

“But how do you decide? And how do you get an overview of the risks? I always keep my end customers in my mind. They all have dreams of their own. They want to explore space or make nanobots that cure cancer, or they want to solve mobility issues. They have one thing in common, they all need chips that are produced by using our machines. The linking pin is the silicon wafer. Our machines turn the chip designs into silicon chips that are produced on the silicon wafers.”

Making chips faster and cheaper

“Chip manufacturers want to produce as many high-quality chips as is possible per day. Manufacturers of devices want to produce as many high-quality devices as possible per day. It is about good chips and affordable chips, affordable devices. That is where Moore’s law kicks in. It is not just about having continuously more power but also about making it cheaper.”

Demand for better litho performance

“This requires new chip designs, which requires chip manufacturers to keep on producing new types of machines. This is how the industry works. Innovation is key. The demand for new machines generates R&D budgets. ASML uses these budgets to continuously improve litho performance, our core business.”

Using AI to innovate

“This is where ASML’s thinking about AI starts. You look at what you can use AI for. This boils down to three things; 1. reducing costs, cost of machines, the cost of ownership for customers 2. reducing time to market and 3. improving customer value. Reducing costs for instance can be done by improving your chip defect rate detection by using deep learning technology or by detecting defective coating, by segmenting and classifying images to zoom in on damaged areas, qualification of parts goes faster.”

Risks of applying AI

“So AI can be useful and brings value, but AI also brings along certain risks. Let us call this the AI demon. These are a few examples:

- AI makes you build solutions that are unexplainable, this is due to models. Models learn from the input you give them and try to predict some form of output. A model tries to figure out some form of correlation but as we all know correlation is not causation. So, then you know something does not function well, but you still do not know why. If you do not understand and cannot explain why things go wrong that is not satisfactory to your customer, your team members cannot fix it and you neither improve the machine designs nor innovate.

- Context dependency is a second issue. Once you have discovered a defect you tweak everything in house in a lab situation, accordingly you achieve the accuracy level that you were aiming for but the model is sensitive to small variations. So, once you deploy it, you notice that it does not work.

- Machine Learning and AI are a commodity. You have to be aware and accept the fact that models and algorithms can be copied easily. Six months after you have built a model, your customers and competitors can do the same. AI is not what gives you a competitive advantage.”

Delivering sustainable innovation by using AI

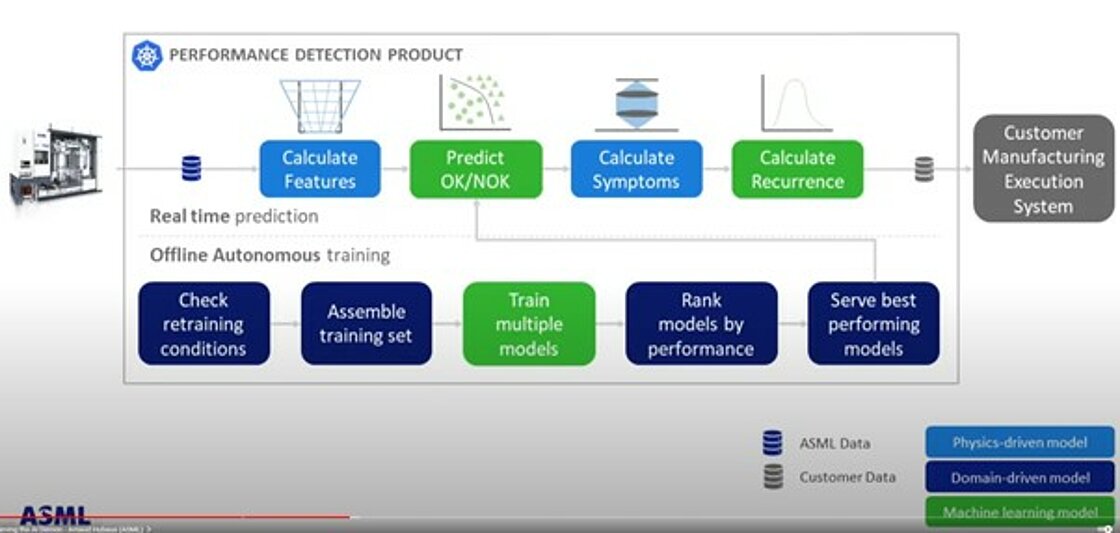

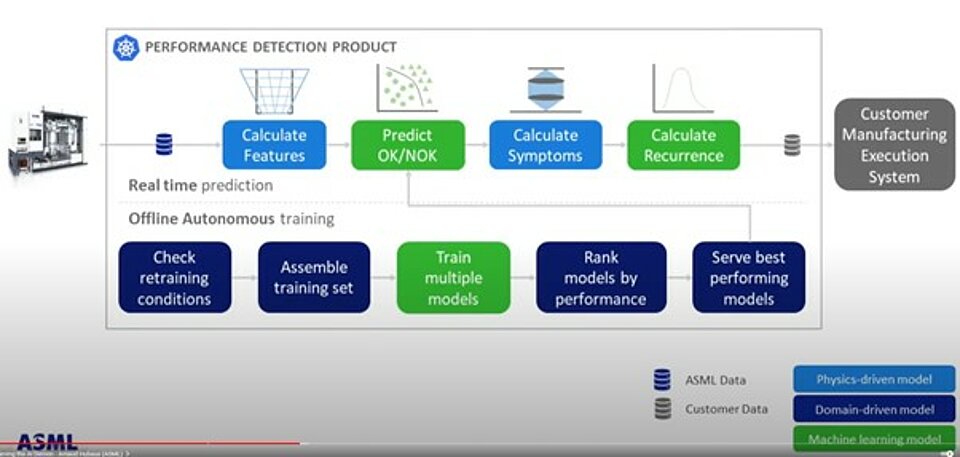

“Then why should you invest in AI? By countering the risks, so by ensuring your output is explainable, context-specific and by accepting that AI is a commodity you can make AI work for you. There are four basic steps your system can go through. They are displayed in the image below. The data comes from the system, from there you can calculate features (they are in fact physical models that give more meaning to these raw data). Next you put this input in a machine learning model, the output of that model can then give you several indications why the system is not ok or present the root cause with a certain likelihood. When it is a recurring issue, you want to schedule some maintenance on the system.”

Invest in the blue boxes

“The blue boxes are your domain knowledge, the unique knowledge that you are bringing to market. These are the subjects you should invest your time and money in: the physical features and the symptom analyses. This means that when you have data that derives from physics or from historic equipment corrections for instance you should use them instead of trying to predict based on data by using an AI-model.”

Build in autonomous retraining and include customer in feedback loop

“When it comes to the context specific element, beware of the fact that variations occur, especially when you are in the manufacturing field, that is completely normal behavior. That is why besides your real-time prediction, you should build in an autonomous retraining system, to make sure that the AI model monitors itself to stay accurate over time. Finally, include the end customer in your feedback loop. The customer can tell you if the result is acceptable. You must include that in your model.”

Define the use-case in which AI can make a difference

“Finally in most cases it is not necessary to build AI models yourself. As I’ve said before it is a commodity. By using existing models, you can go a very long way. What makes the difference is the quality of your data and the quality of your physical models. If you know your industry, then focus on those use-cases in which AI can make a difference. Make sure that is explainable and context specific. Your unique differentiator is what makes you successful and that is not Artificial Intelligence in itself. AI helps ASML to optimize for a very specific context, by adding a layer on top of what we do we can really squeeze even more performance of our system.”