DENS: Clean energy at the press of a button

As young entrepreneurs, Max Aerts and Tijn Swinkels are still far from achieving their life's work: accelerating the transition to sustainable energy usage through the use of hydrozine ('formic acid'). The point is: time is short. These two innovators from Brabant are in a hurry because the world urgently needs their clean generator technology.

Any festival worthy of the name is powered by a long row of noisy generators that consume hundreds of litres of diesel. Diesel is one of the most polluting fuels that exists, but still relatively cheap. A thorn in the side of Max Aerts and Tijn Swinkels, because the public bears the brunt of the consequences: impaired health and environmental pollution with all the associated knock-on effects.

They see a clean and easy-to-use alternative: hydrozine, a safe fuel that can be produced sustainably using green electricity. Their shiny company brochure presents this dream. A clean generator in a sleek, dark-grey cabinet producing electricity on a building site in the middle of a busy city. Soundlessly and without emitting harmful fumes.

Hydrozine as an energy carrier

In the near future, their company DENS (Dutch Energy Solutions) will present the first generator that uses hydrozine to generate electricity. It is the result of endless experimentation, not being afraid to make mistakes, trying out new parts and persevering in the face of seemingly unsurmountable problems. The founders and their team members have been working up to 80 hours a week on this project. “But it doesn't feel like work”, says Max. “It’s as though we are caught up in an exciting adventure story for boys.”

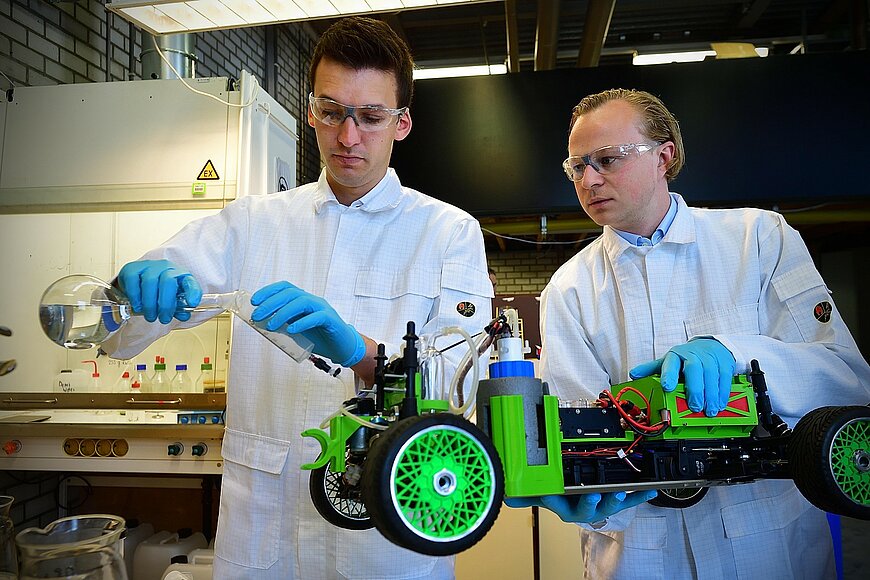

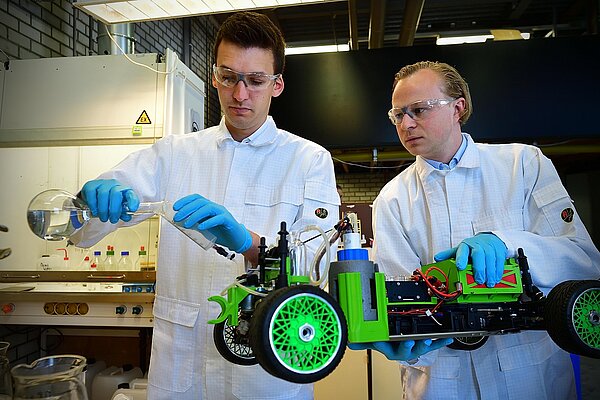

It all started back in 2015 when they were students at Eindhoven University of Technology and succeeded in using hydrozine to power a model car, their first working prototype. The technology already existed, but using it to power a car was completely new. “Watching that little car pulling away for the first time was a really cool experience”, Max says as he remembers the feeling of triumph he experienced back then. “It was as though you had invented a completely new fuel.”

Energy yield

The University gave them the opportunity of developing this hydrozine application further via an honors program and then in a student team. They won the sustainability price for it in 2015 and received a sum of €5000 to invest in further research and development. With the support of 70 companies as sponsors, that student team (Formic Acid Sustainable Transportation, or FAST for short) succeeded in proving their idea on a larger scale. Team FAST produced a second car that managed to increase the energy yield of the first model car 42 times over.

Newspapers and news channels all over the world published and aired stories about the students who were trying to revolutionise the automotive universe. “We were the only researchers in the world to have succeeded in making a working model of this size,” says Tijn.

Formic acid

Hydrozine is better known as formic acid, one of the oldest and simplest acids known to mankind. The acid is produced by binding hydrogen to CO2. It is a liquid that can be pumped into a fuel tank just like petrol or diesel. The car converts it back into CO2 and hydrogen.

Some ants use this acid as a repellent, which explains the name. DENS has nothing to do with ants though, as their fuel can be produced from natural gas or bio gas. When produced in a sustainable process using green electricity, which is what they originally intended, Max and Tijn prefer to use the name hydrozine for their energy carrier.

Their machine converts hydrozine into hydrogen. Hydrogen is clean, because it only leaves water vapour behind when burned. However, hydrogen is a highly flammable and explosive gas. Expensive, high-pressure tanks are required to store this gas safely. The entrepreneurs want to overcome the disadvantages of hydrogen by using hydrozine as an intermediary form. Hydrozine has the advantage of being liquid at room temperature, so it does not have to be transported in tanks at an extremely high pressure. This makes it safer, cheaper and easier to use as an energy carrier in comparison to hydrogen.

Clean technology

Developing a car powered by hydrozine turned out to be too ambitious a goal. They now see more potential in stationary machinery: generators, excavators and other heavy-duty applications. “Unlike a car, which can be driven to a refuelling station, fuel has to be transported to a generator”, says Tijn. “And that makes a hydrozine-based solution on construction sites or at festivals much more logical.”

Construction company BAM Infra and other parties have now come on board. “From a marketing point of view, developing a generator that runs on hydrozine is less sexy than a car”, says Max, who is responsible for the company’s commercial activities. “But if generators no longer have to be powered by diesel, the environment will benefit significantly. We now know that the world is eagerly waiting for a solution like this.”

“This is our purpose in life, so we’re unstoppable. Every step is an inspiring new milestone that gives us new energy.”

Multidisciplinary

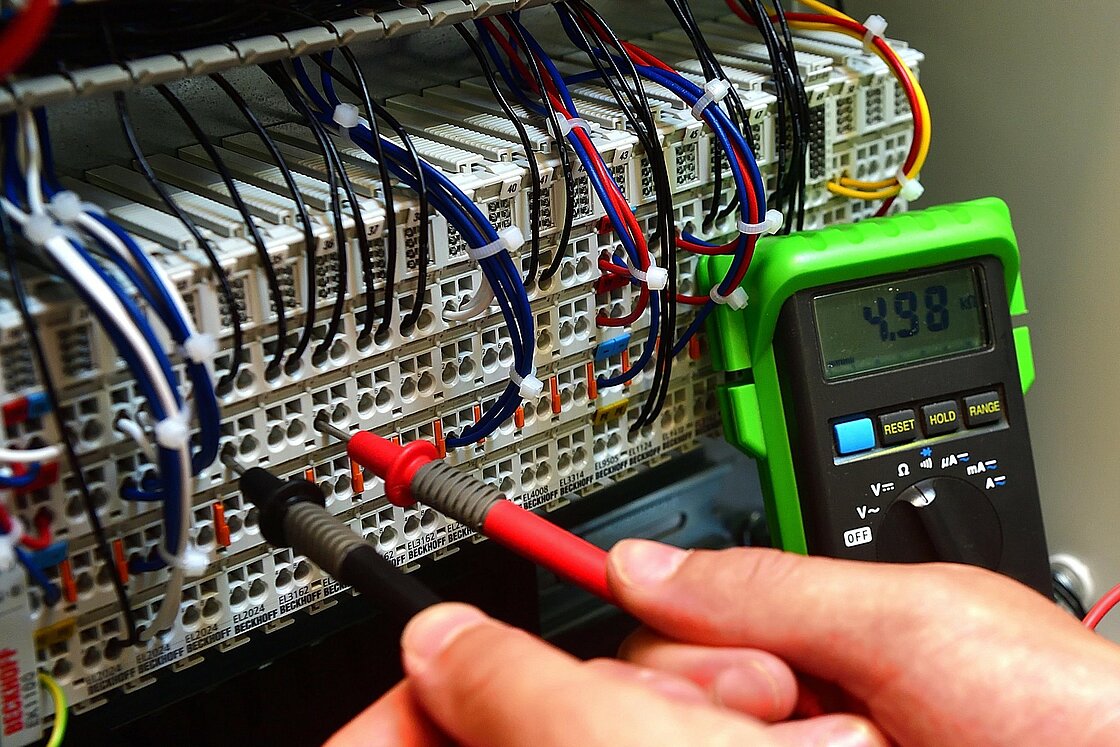

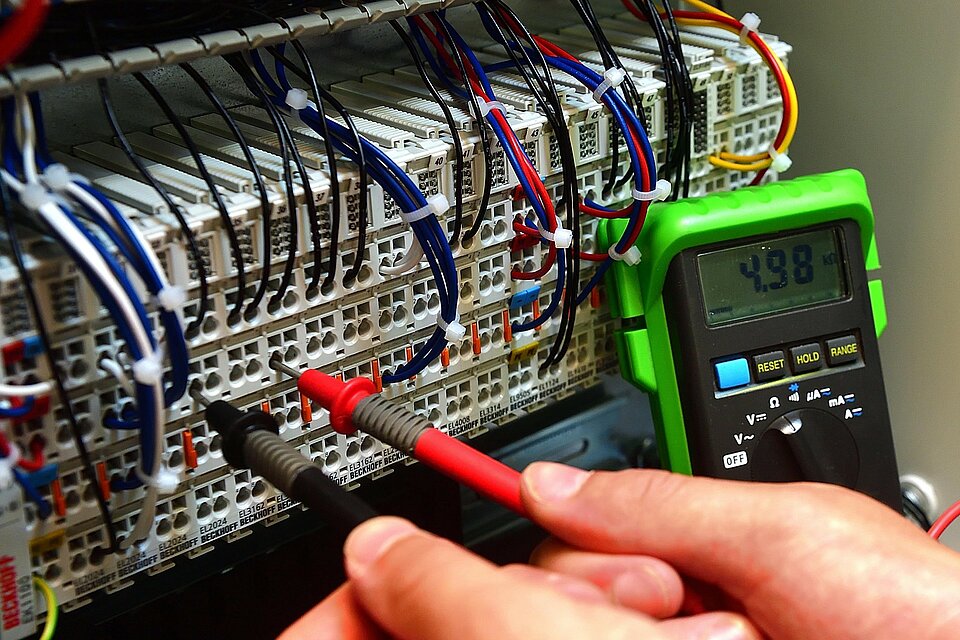

They have formed a start-up business and are currently developing their idea further at the automotive campus on the site of the old DAF factory in Helmond. They use the former boiler house as a laboratory. Their test rigs have been set up here, surrounded by hoses, spanners and electrical wiring. This is multidisciplinary work: chemistry, industrial design, electrical engineering, physics and mechanical engineering all in one.

The energy yield of their new hydrozine generator is a huge improvement compared to their previous version; 1000 times higher. Their biggest challenge is to find a business model that is economically viable. “Technically you can solve everything, as long as you continue to fine-tune your engineering”, says Tijn. “At the moment though, mainly due to the small-scale production approach, our solution is still more expensive than diesel. What we need to do now is create demand for our product.”

Their confidence in hydrozine has not waned at all. They feel like they have an immensely powerful key to the energy transition in their hands. With maximum convenience and simplicity for the user, who just has to push a single button. And based on a liquid fuel, so refuelling is exactly the same as the procedure for the familiar fossil fuels. They know that that is important. “Because getting users to change their behaviour, now that’s a challenge!”

Only possible in Brabant

They now have many contacts with suppliers and customers. That helps a lot, Max says. “We benefit from the presence of many other partners here in East Brabant - they offer us expertise, sponsorship, parts and other necessities. We can only do this in Brabant."

They have also benefited enormously from assistance provided by the students of the Technical University, who have voluntarily invested their time in this project. Tijn: “We have been in the media limelight a lot and we receive huge support from professors, TNO and other experts. We are pretty well known in these circles.”

Hydrogen economy

Out of the public eye, they have been working hard in their laboratory in recent months to perfect their generator, which converts hydrozine into hydrogen. Now they feel that the time has come to show the world what is possible. “The hydrogen economy shows no signs of taking off,” says Max. “That’s a problem we can solve, so rapid growth should be on the cards.”

Their kick? They, together with the whole team, enjoy nothing more than seeing their generator run perfectly as the hydrozine does its job. But they also want to show the world visible proof. “We are going to prove what we have been claiming for the past four years”, says the duo. “We don’t want to be a promising project that ends in failure. Innovation is always associated with a process full of uncertainties.

Developing something new always takes more time and costs more money than you thought originally. So now we’re going to prove that it really is feasible.”

They had no idea that they would ever reach this stage when they developed their first car at university. “This is our purpose in life, so we’re unstoppable”, says Max. “Every step is an inspiring new milestone that gives us new energy. We are creating something completely new that will benefit many people.”