Working on a perfect machine for world’s most advanced microchips

As a product architect at ASML, Giovanna de Simone from Italy is responsible for the design of the wafer table module in ASML’s lithography machines. By doing so she contributes to building a perfect machine that prints the most advanced microchips on earth. Technical complexity is what drives her. ‘Sometimes it is hard for me to disconnect after work, I simply keep laying pieces of the puzzle in my mind.’

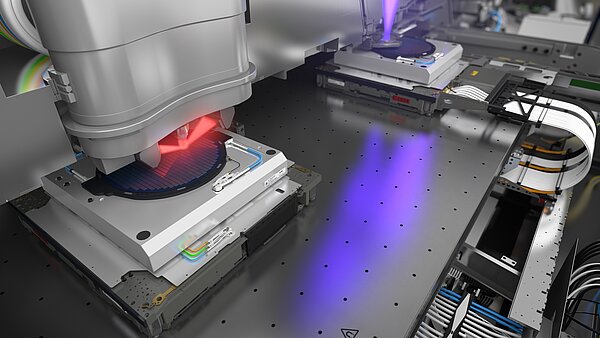

“With my team I am responsible for defining the design for the new wafer table module in ASML’s machines. It is a module that holds the wafer during the printing process. It physically holds the wafer and must be free from all sorts of mechanical and thermal disturbances to be able to print with nanometer accuracy. To give an idea of the technical challenge: temperature is controlled in the order of 0.001 Celsius, position is controlled in the order of 1 nm (0.000001 mm) while wafer is moving with an acceleration of about 88m/s2 (higher than the acceleration of a Tesla!).”

Performance requirements are leading but there is more

“The module has to meet the performance and lifetime requirements of our customers, who produce millions of wafers per year. Moreover, ASML has a continuous focus on sustainability. Each part must be made in a way that it can be re-used when the machine or module reaches its end-of-life. On the one hand reducing waste means being sustainable for the environment and society. On the other hand, reducing waste also leads to cost reduction so there is additional value in re-use.”

Extremely diverse team

“The team I work with is very diverse. It consists of tribology experts, mechanical designers, material scientists, thermal scientists, and data scientists who analyses performance data. The team is also really diverse, when it comes to cultural backgrounds. I have colleagues who come from India, US, China, France, Germany, Greece, the Netherlands and more. And it is a nice mix when you look at gender, age and work experience.”

Building a perfect machine to print the most advanced microchips

“What we are working on is really innovative. Working in the lithography field means working on today’s technology. We are trying to prove the impossible by building a perfect machine so that we can print the most advanced microchips. Chips that are not only smaller and more powerful but also need to be printed faster to feed the growing and demanding market. We are driving Moore’s law, which is actually not a law but a prediction.”

Connect with R&D to push boundaries of what is possible

“ASML invests billions of euro in R&D every year and has a really large research department, that works closely together with technical universities all over the world. To push the boundaries of what is possible we connect with our research department so that we can quickly use their findings. We then look at what is valuable for our design when it comes to material, design etc. Our daily work consists of simulation, field data analysis, inhouse testing and prototyping at full module or at sample level. During this process we work according to a feedback loop. We start at system level and then accordingly move to module and parts level and then go back to module and system to verify that specifications are met.”

Technical complexity drives me

“I am a mechanical engineer with an expertise in thermal competences, my PhD was in fluid dynamics and thermal dynamics. Within ASML, I’ve had various roles and currently I’m a product architect. I am really fascinated by the motion of a fluid and amazed by the fact that an equation can describe and predict its behavior. Technical complexity is what drives me and building up the knowledge to solve something and think of the perfect design and related physics is what I find really appealing. Sometimes it is hard for me to disconnect after work, I simply keep laying pieces of the puzzle in my mind.”

Looked for a challenge in Europe after finishing PhD

“Originally, I come from Southern Italy. Later I moved to Rome where I studied mechanical engineering and got my PhD at the university of Rome ‘Tor Vergata’. After my PhD I was looking for new opportunities. I wanted to take on a challenge, but Southern Italy does not provide you with a lot of job opportunities in the engineering field and to me it did not matter much if my job would be in the Northern Italy or in the rest of Europe.”

An unknown company with major impact and lot of opportunities

“When I started looking for companies, I did not know ASML, but when I came across ASML I soon discovered that ASML really had a big footprint in my life. As a market-leader in lithography machines that are key in producing chips, ASML has an enormous impact. I was and I am, surrounded by microchips that have been printed with an ASML machine. And so do you! Just look at your phone, laptop, or car, for example. And think about the impact chips have in medical care. When I was looking for a job, I also spoke with a company in England but ASML offered me more opportunities for personal growth. ASML offers lots of opportunities to develop different competences or work on different modules and in different roles.”

Brainport Eindhoven is a very international region

“I had already got to know the Netherlands and the Eindhoven region as I studied at Eindhoven University of Technology for a while during an Erasmus project. Back then I chose TU/e because the course was taught in English. At that time, I already experienced how international the region is with so many different cultures. So, in 2013 I moved to Eindhoven and started working at ASML.”

Good work-life balanced and structured, well organized

“Living in the Netherlands is good. It offers you a really good work-life balance. Lots of daily routines can be done by bike. I for instance drop the children at daycare by bike and then bike to work. It is timesaving and gives you energy. There is also a great diversity in supermarkets that offer Italian products. ASML’s restaurant has an Italian corner as well with two Italian chefs and an Italian bartender, their food and coffee feel like home. Moreover, the city of Eindhoven is well-organized with lots of green areas. Furthermore, there are lots of facilities here.”

Considering moving to Brainport Eindhoven? Just try it

“My advice to other internationals who are considering moving to Eindhoven would be: don’t be skeptical, just try it. You will see that you join an international community, and the work-life balance is an absolute plus. I want to give my kids another opportunity in life and that is what Brainport Eindhoven offers with all its facilities, education and opportunities. They are not even four years old and they already speak three languages!”