About VDL ETG

Talent

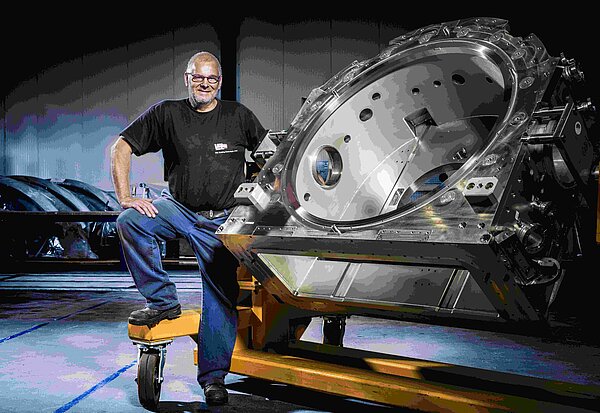

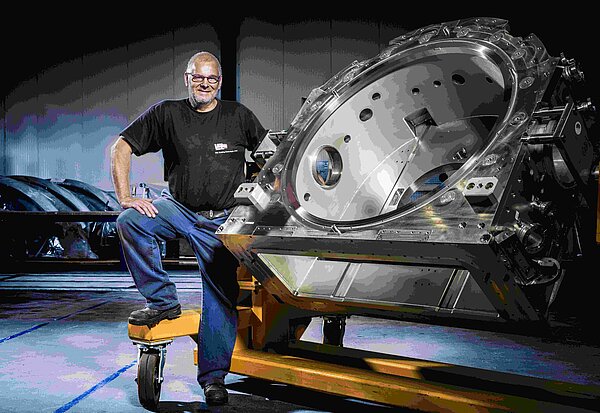

System architect Pierre Rompen has been working at VDL ETG T&D for more than seven years. In his position, his responsibilities include the technical realization of a product or subsystem within various projects. He has contact with colleagues in the development team, suppliers, management and customers. He gathers customer requests and translates them to the development team who all bring in different disciplines and expertise. System architect Pierre Rompen has worked at VDL ETG T&D for over seven years. In his position, his responsibilities include the technical realization of a product or subsystem within various projects. He has contact with colleagues in the development team, suppliers, management and customers. He gathers customer requests and translates them to the development team, which includes different disciplines and expertise.

Discuss, Design and Deliver

"In my job, the art is to assess what is needed to make a development successful and how to answer the customer's wishes. You do this by discussing all possible crucial aspects of the system design with the team. You often encounter critical technical challenges, but then it is important to give the design as much added value as possible, resulting in a successful delivery to the customer. "

Room for own input

"It varies per project to what extent there is room for freedom. Sometimes a large client comes along with a lot of money, resources and space to develop expertise. You then go into such a project in depth by getting everything out of an existing concept. These framed assignments can be long and allow you to work in detail.

Other times you work on an entirely new product from a client, and they give 'carte blanche,' so to speak. An open assignment gives you a lot of freedom of movement as an architect and allows you to be completely immersed in the technology. Either way, there is always a project that you are excited about and find more than enough technical challenges in it."

Highlight

"We were allowed to design and build a new product from scratch for an American client. Against all expectations, we delivered a product that met all requirements within the deadline. But this was not without blood, sweat and tears. The first time we wanted to show the product, we stood in the room with management and the customer, full of expectations, after which the product did not work properly. Eventually, we solved this as a team by taking distance and testing purchased components before assembly. Currently, 4 to 5 of these machines are already running worldwide."

Strength through cooperation

"What defines VDL ETG is the general mindset of 'Strength through cooperation.' As a team, you work on a solution to a technical problem; you spar, discuss, brainstorm, implement and evaluate to reach a common goal ultimately. Because we work for multiple clients, we offer different projects. You will have many responsibilities, and depending on the project, there is room for your own input and personal development.

By bringing development and production under one roof, VDL ETG distinguishes itself from its competitors. Here, innovative ideas are converted into advanced products that you see become a reality in the facility and factory. You are involved in the entire life cycle of a product; one moment, you are sitting behind your computer assessing the results of complex multi-physical analysis, and the next moment you are in the working room screwing things together. This hands-on mentality lives throughout the organization."

Societal Impact

VDL ETG is one of the most influential companies within the Brainport Eindhoven region. Although they provide integrated technology hidden from society's eyes, they are indispensable during the development and production of complex machines, components and finished products that contribute to the world of tomorrow.

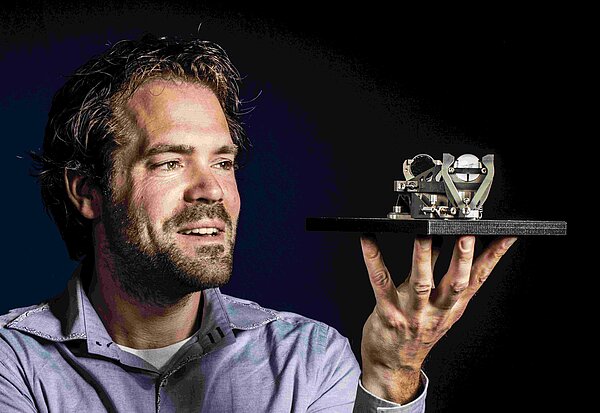

The company is a key player in developing and producing global chip manufacturing systems. Whether it is the development and production of the wafer handler subsystem, the EUV light source module production or the realization of the precision-made aluminium frames, VDL ETG has left its footprint in making the world a bit faster.

Beyond that, VDL ETG also supplies products to the so-called analytical market, such as the electron microscopy and spectrum microscopy used for medical and materials research.

In the medical industry, they are also involved in pioneering technological breakthroughs. For example, the company supplies precision parts for particle accelerator systems that deliver highly targeted radiation to malignant tumours. These systems are also used for fundamental research.

VDL ETG proudly helps its high-tech customers to gain a competitive advantage. They are that partner that makes its customers think, reflect and rethink. And they are that club that allows customers to implement innovations - all for the greater good, with safety, sustainability and cost efficiency in mind. Through all these developments, in collaboration with its employees, partners, suppliers and customers, VDL ETG builds a healthier and smarter world every day.

Brainport Factor

VDL ETG believes a unique empowering factor exists in the Brainport Eindhoven region. It consists of the fact that knowledge developed for one company can be reused for product development for another. You might expect that a company that uses new knowledge for its product improvements, and has paid for it, would want to keep the knowledge private from its competitors. However, there is a general consensus that sharing knowledge automatically leads to new knowledge, which benefits all high-tech companies in the short and long term. That is the power of an open technical community. It also contributes that the major players in this region that bring complete systems to the market operate in different fields and are, therefore, not competitors with each other.

VDL ETG plays a larger role in developing the major system builders than expected. For example, VDL ETG develops and produces so-called 'material handling' systems that work within a vacuum. Working in a vacuum imposes specialized requirements, such as the materials' cleanliness. And this knowledge can be used for both lithography systems and electron microscopes. VDL ETG believes in the power of contribution and shares the same mentality as the Brainport Eindhoven region: collaboration is key to success.