SMART Photonics links cutting-edge technology to a market need

Photonics is more than a vague promise, says Richard Visser of SMART Photonics. "We are on the eve of something earth-shattering. Rather like the upheaval caused by the electronic chip.”

“We really are on the eve of an earth-shattering development. Rather like the upheaval caused by the electronic chip.”

He talks about how radio has developed. The first devices were tube radios. Then transistors arrived on the scene, leading to the transistor radio. “This development led to a major reduction in size and somebody came up with the idea of fitting radios to cars.” So development of an existing product, the radio, led to a completely new market in the automotive sector. “And now you have a chip in your smartphone which allows you to receive radio signals.”

ASML, Intel and NXP

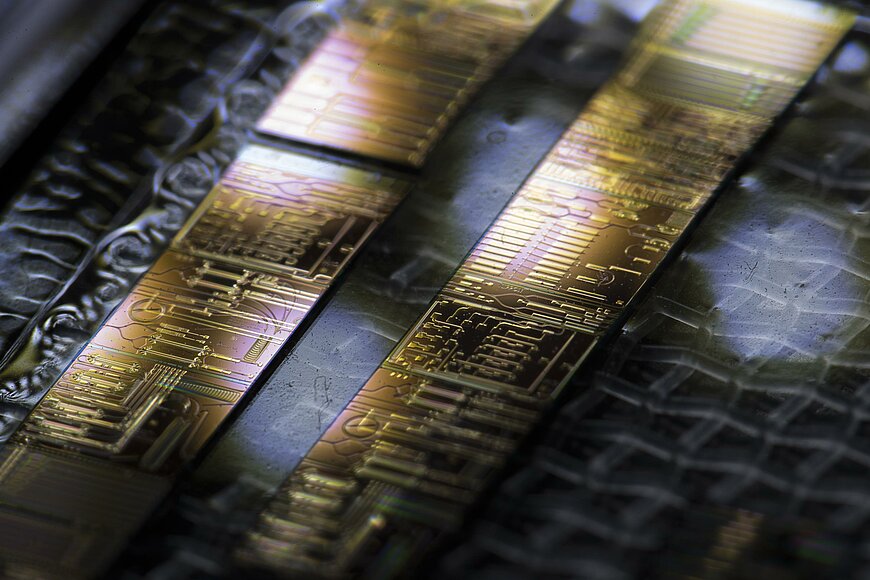

Visser's background is in electronics and the semi-conductor industry. He worked previously for ASML and Philips, among others, and has experienced at first hand how the semiconductor industry has developed into what it is today. “The way in which the semiconductor industry has developed has opened up the door for major corporations such as ASML, Intel and NXP.” Visser believes that photonics will develop in a similar way. With semiconductors that use an indium phosphide (InP) platform rather than silicon. “The most important capability in our chips is the ability to generate light and we can only do that with indium phosphide (InP). The manufacturing process is similar to that for electronic chips, but also requires specific skills and experience. We look for people who have experience with silicon chips and then train them in-house to give them the skill set we require.”

This technology is completely new and mainly based on lasers used for telecommunications, Visser explains. “Photonics has been around in the telecom industry for more than forty years. However, producing complex photonic chips with a staggering amount of different components mounted on just a few square millimetres is completely new. All the more so because these chips can also be used in other markets such as aviation, healthcare, medical technology and automotive.”

TU Eindhoven

“Until recently, making a chip based on this technology was extremely difficult. Production was only possible on a very small scale and required highly qualified technical people. During the past twenty years, Eindhoven University of Technology (TU/e) has developed this technology to a point where it is now comparable with electronics technology. They invented a system based on standard building blocks, just like Lego. These building blocks can be combined to deliver new functionality, i.e. a chip. The customer uses software to produce a chip design, sends that design to us and we turn it into a chip that the customer can use in his product.”

“Developing technology is one thing, but ultimately you also have to be able to produce and sell a tangible product.”

Visser markets photonic chips via SMART Photonics. “Developing the technology is one thing, but ultimately you also have to be able to produce and sell a tangible product.” SMART Photonics, including the chip factory, is housed in the same building where he used to work as a Philips employee; High Tech Campus 29. The photonic components, lasers on InP, were also developed in the same building during that period. That particular department closed in 2011. Visser offered the department’s former employees a job working with the same technology, and more than fifty experienced people now work at SMART Photonics. “They primarily contribute knowledge and skills in the area of ‘making’ the product. Add TU/e's twenty years of development experience with this new technology to the mix and the result is SMART Photonics. This is our recipe for conquering the world.”

Added value for the Dutch economy

“Six years ago, photonics was abracadabra for most people. Very few people in the world were capable of making this kind of complex chip at the time.” In 2013, SMART Photonics announced a world-first: a Multi Project wafer with fifteen different chips for fifteen different customers. The chips are made on wafers of this type - a round disc measuring 7.5 cm in diameter. “That was when we launched this new technology in the market for the first time.”

“We couldn’t have been happier. The chips we were producing exceeded all our expectations.” Visser wants to grow substantially as a manufacturer of these chips, but he also sees added value for the Dutch economy. “Simply put, we feel that this new technology has enormous potential, not just for us as a chip manufacturer, but also for companies that will be able to improve existing applications, or even create new applications with the chips. But we can't achieve this on our own. That need for collaboration ultimately led to the birth of Photon Delta.”

“We couldn’t have been happier. The chips we were producing exceeded all our expectations.”

“At the time, I literally said: SMART Photonics is a tiny sapling in the midst of a landscape full of promise. If we want our tiny sapling to grow into a robust tree, we will have to develop the landscape.” In collaboration with the CFO of SMART Photonics, Robert Feelders, who was still working at TU/e at the time, we brought together a group of twenty people: users, professors and officials from local and regional government organisations such as municipalities and provincial authorities. They could also see the potential and that meeting led to the creation of PhotonDelta. Then all the parties put money in the pot in order to commission an initial market report from Berenschot. “Today, almost five years later, Ton Backx and Ewit Roos, who are the driving force behind PhotonDelta, can look back on some tremendous achievements. For example, you now see central and local government embracing photonics.” Visser was there on 15 July when Rene Penning de Vries, the face of Photonic Netherlands, presented the National Photonics Agenda to the State Secretary for Economic Affairs and Climate, Mona Keijzer.

However, raising capital is still a major challenge. “High tech companies always have trouble raising capital. Particularly when that capital will be used to develop a technology that is not yet understood by everybody. So we face enormous challenges. We need to make people enthusiastic, convince them that something really special is happening here and that we need money to develop it. So far, we have been very successful in raising capital to fund our growth. Our customers play a particularly important role here. Fortunately, the market is interested in our technology. Large companies are keeping track of our achievements and are particularly interested in our capabilities.”

“High tech companies always have trouble raising capital. Particularly when that capital will be used to develop a technology that is not yet understood by everybody.”

Actually spending the money has proved to be even more difficult. He analyses and re-analyses the usefulness of every single capital purchase at least five times. “I clearly remember buying the first machine. The manufacturer wanted 300,000 euros for it. It took a bit of talking and negotiation, but I was eventually able to buy the machine for 240,000 euros. And then I had to transfer the money. I sat with my finger hovering over the button for half an hour as I checked and rechecked whether I had filled everything in correctly.”

Visser compares the start-up phase with a baby or toddler. “Everything is fun and new and you learn all the time, mostly through falling down and picking yourself up again. The next stage is adolescence, which is where SMART Photonics is at the moment. You have to take grown-up decisions, but you are not yet really ready to do so. At the moment, our focus lies on stabilising the processes for making the chips so that we will eventually also be able to produce large volumes. And more and more new people are joining the company in new positions, e.g. our communications advisor and quality & safety manager. They are also responsible for ensuring that the organisation reaches maturity.”

Like any fast-growing company, things also go wrong regularly. For example, several machines broke down at the end of last year and it felt like everything that could go wrong had gone wrong all at the same time. “A perfect storm”, is how Visser refers to that period. “But you have to endure growing pains in order to reach adulthood.” That is what Visser wants: to quickly become a mature company that can supply the best chips in the world to the largest companies in the world in large volumes. To achieve this, he has to invest at the right time to ensure that a factory capable of mass production is ready and waiting.

“Many of the companies in our sector, such as ASML, are going out of their way to help us. We can also count on huge support from TU/e, the Municipality of Eindhoven, the Provincial Authority of North Brabant, the Dutch government and Europe. The technology is extremely promising and expected to significantly boost employment and the economy.”

Visser is confident that both the technology and the company will be successful and that the tipping point is not far off. “In ten years' time, you will be reading emails or watching a movie as your self-driving car silently transports you to your destination. And you may even remember this conversation and say to yourself: Wow, Visser was right. They did it.”

SMART/EFFECT Photonics is a partner in the Dutch initiative called PhotonDelta. This public private initiative aims to grow an ecosystem of integrated photonics. Companies, knowledge institutions and governments combine efforts in the supply chain in order to grow the business, and thereby the number of companies and employees working in this industry.