Airbus takes its additive manufacturing from prototypes to series production, from Taufkirchen to Bristol

After three years of prototyping with Additive Industries‘ MetalFAB1 in Taufkirchen (near Munich), Airbus’ daughter company APWORKS has decided to scale up to series production for its aerospace industry. Therefore, this part of APWORKS’ business will be moved to Bristol, England. APWORKS was Additive Industries’ first customer and has extensively tested the MetalFAB1 Beta system since its installation in March 2016. Additive Industries is a young company headquartered in Eindhoven.

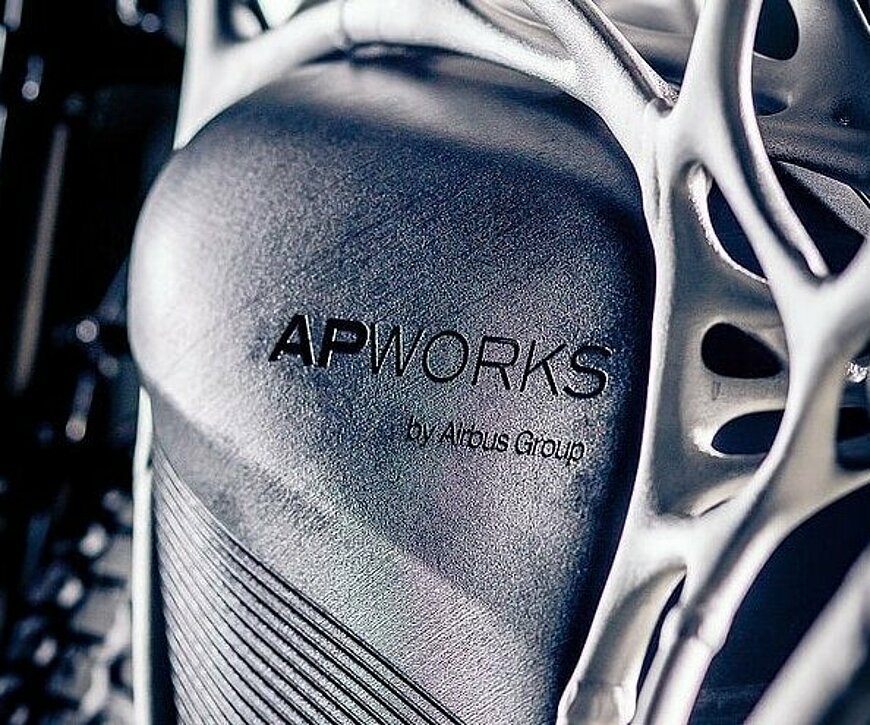

APWORKS’ main focus in Taufkirchen is on development and production of complex applications for metal additive manufacturing in non-regulated industries such as automotive, robotics or tooling. That’s why series production for the aerospace industry – a different business – will be done closer to actual production at the new Additive Industries Process & Application Development Center on the aerospace campus in Filton, near Bristol.

APWORKS CEO Joachim Zettler believes metal additive manufacturing (3d printing with metal) will continue to evolve into a mature fabrication technology and will be able to compete with conventional processes like casting, machining and powder metallurgy. “In the next years we expect this market to continuously grow and especially in the aerospace industry, new airplanes and aero-engines will contain a substantial number of parts that are additively manufactured.”