22 April 2024

Internationalization of education calls for collaboration

- Education

- International talent

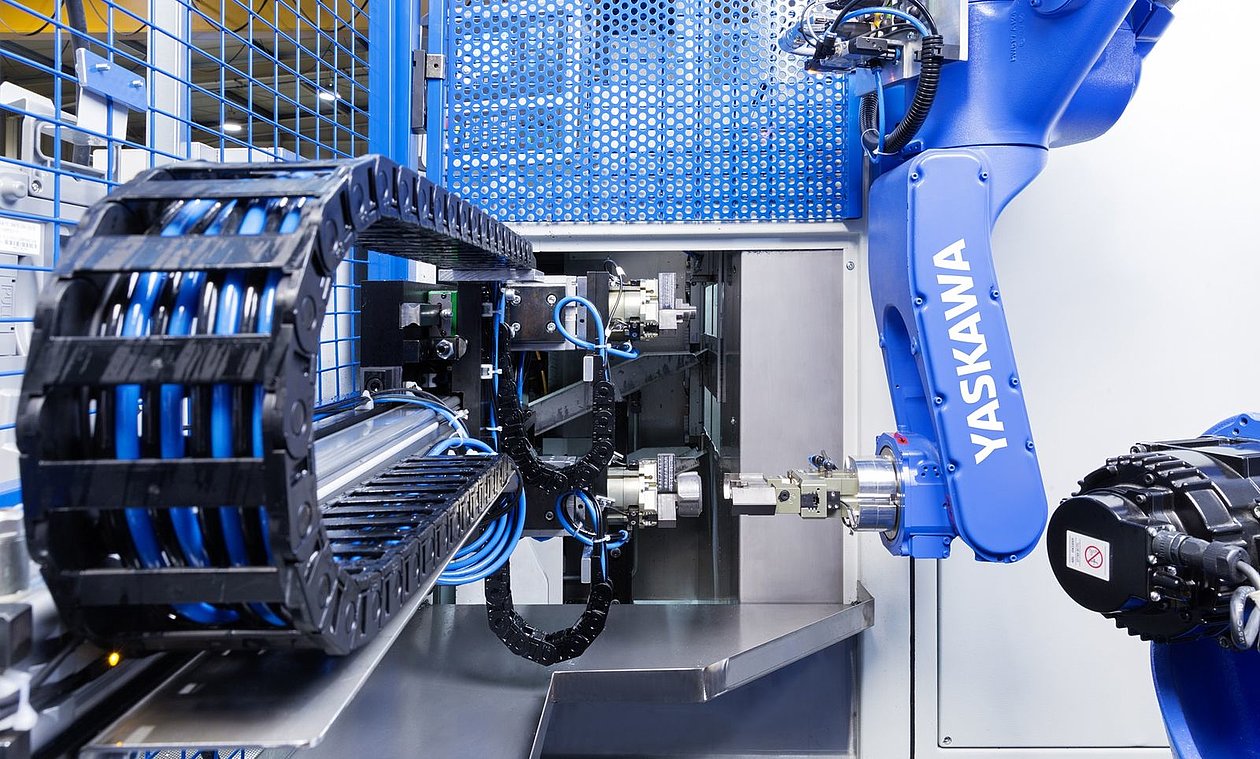

Yaskawa, a Japanese company with offices all over the world, makes robotic systems and software for production processes. The company chose the Brainport Industries Campus (BIC) in Eindhoven, as they wanted to be part of the factory of the future. The company is working with various other parties on a factory that can run day and night. Eddie Mennen, managing director at Yaskawa Benelux, talks about the decision to move to the BIC. “It started about eight years ago with the establishment of Brainport Industries where all kinds of companies from the manufacturing industry started to work together to accelerate innovation, among other things. That collaboration was never really visible, but the desire to make it concrete was there.”

That physical place was created with the Brainport Industries Campus, a centre for the high-tech manufacturing industry, says Mennen. “All the companies located here make very complex things, often in small volumes. That makes it different from mass production, where one product rolls off the production line in large numbers. Here production lines need to be able to switch quickly between different products or specific adjustments, because not everyone asks for the same thing. A conveyor belt is not enough for this type of production. It requires a different way of thinking,” Mennen explains.

Yaskawa, for example, recently worked with KMWE, Rubix and Ijssel on the development of a fully automatic vehicle (FAVs) with a robotic arm to exchange automated tools in CNC machines. Mennen: “We do this in the Advanced Manufactured Logistics field lab. Every party contributes knowledge; Rubix is good with FAVs, Ijssel has developed the IT system and we have focused on the vision. Such a vehicle must stop very accurately in front of the equipment so that the robotic arm can pick up the right parts. By sharing this knowledge and expertise, we can develop beautiful things faster and save costs. We also involve as many suppliers as possible in the work on this product in the process. This ensures that things that are envisioned can be put into practice more quickly. That’s only possible with intensive cooperation.”

"By sharing this knowledge and expertise, we can develop beautiful things faster and save costs."

Eddie Mennen, Managing Director Yaskawa Benelux

Knowledge sharing

According to Mennen, this exchange can only happen if companies can easily come together. “And that’s made possible here at the Brainport Industries Campus. The lines are literally shorter because you meet each other in the Atrium or just visit people. Plus, it is also good for the atmosphere because you see each other for Friday evening drinks,” Mennen says. Between sharing knowledge, collaborating in field labs and the short lines of communication, Mennen believes that the companies on the campus are able to take the next step more quickly, such as towards automatic programming, for example: “In the High Tech Software Competence Centre, companies are working on one-on-one simulations of reality. Here, production processes are simulated so that you can test whether it works well in practice. This results in a lot of data, so the next step is to use this data to write automatic code for machines. All parties on campus benefit from this.”

“There are still boys and girls in high school who think that technology will make your hands dirty”

Eddie Mennen, Managing Director Yaskawa Benelux

“The great thing is that the campus has an inspiring function. Normally you wouldn’t be able to see so well how this works. When the Atrium is completely finished, it will look attractive and open with a lot of glass. Visitors will get a better idea of what exactly the high-tech manufacturing industry does. This also has a positive impact on education. There are still boys and girls in high school who think that technology will make your hands dirty. On campus we show that the opposite is true.”