04 April 2022

The first round of Hello Mentor has been completed

- Arbeidsmarkt

- Entrepreneurship

- International talent

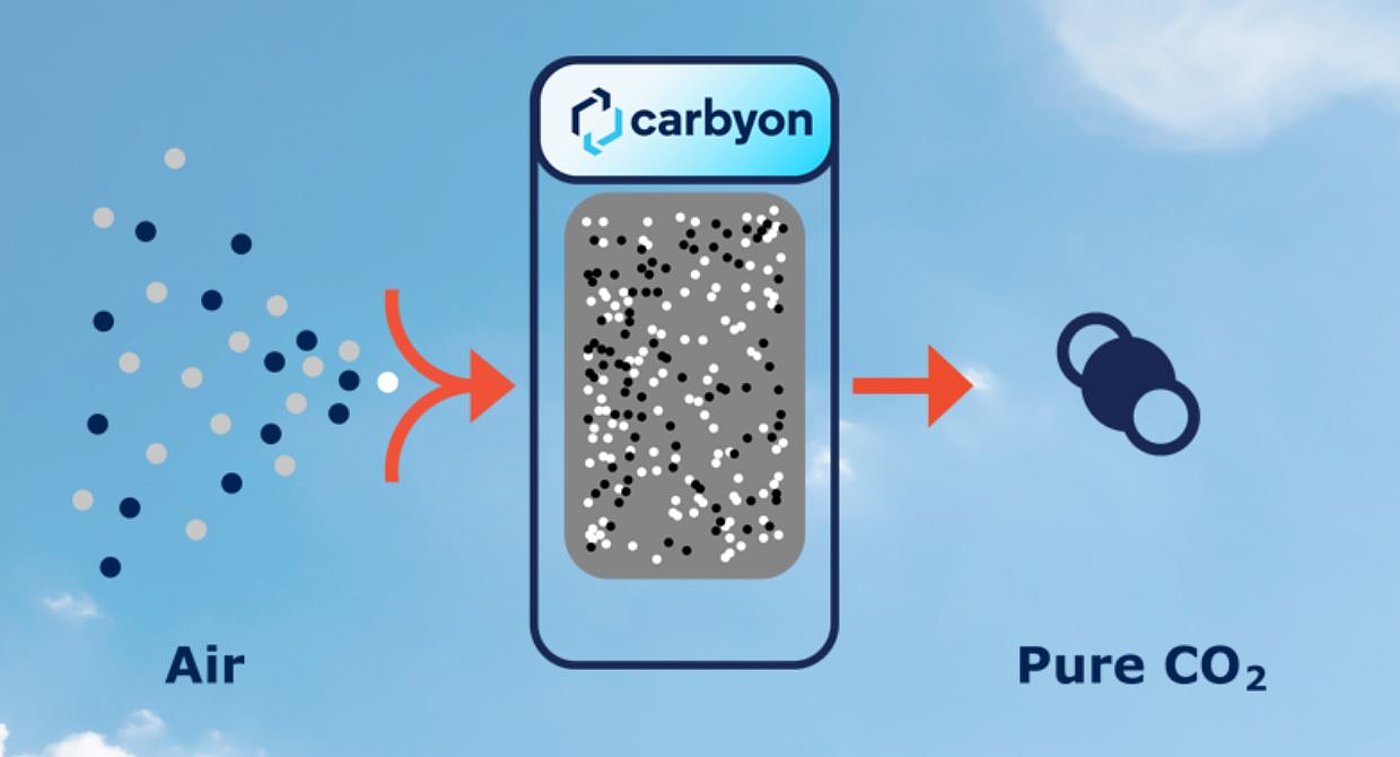

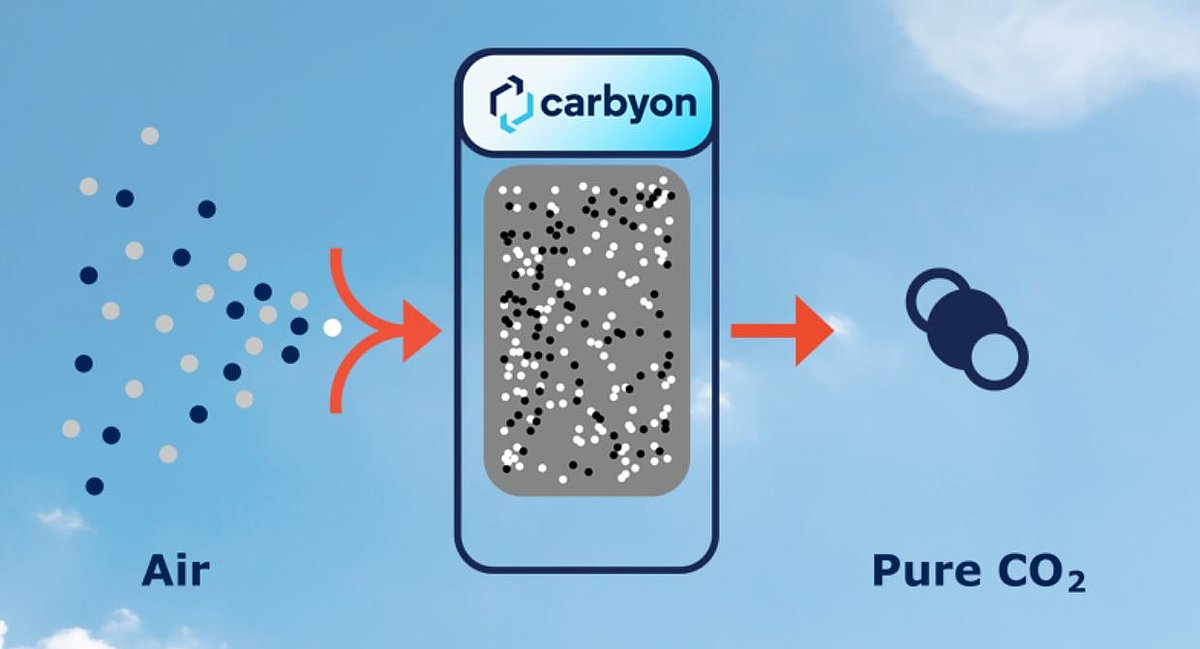

Innovation Origins rewarded Carbyon with a Gerard & Anton Award in July. Carbyon's machinery filters CO2 from the air and supplies it in a purified form to make kerosene for aircraft

When physicist Hans de Neve was still working at TNO (the Netherlands Organisation for Applied Scientific Research), he, just like all the other employees, had the opportunity once a year to work out an idea that was perhaps not immediately obvious. For some time he had been thinking about the use of CO2 in making fuels more sustainable, and about the climate targets aimed at reducing CO2 emissions.

But what if you could filter CO2 out of air? And purify it in such a way that it would be suitable to make kerosene from it after a reaction with hydrogen? And in such a way that the product could compete with kerosene that is distilled from petroleum?

He was already familiar with the function of thin film technology that is used in solar cells from an earlier project. The film converts light into electricity. But that same film can also be used to extract CO2 from the air if you treat it with an absorbent agent, which is referred to as a sorbent.

The material of the thin film technology that De Neve and his company, Carbyon, use is highly porous. All pores are treated with this sorbent. This allows an enormous amount of CO2 to bind to the thin film. The CO2 is released once it has been heated up to a temperature of 100 degrees Celsius. Pure CO2 gas is then produced. Carbyon captures this gas and it can be sold to be reused in industry, such as for the production of green kerosene.

Project manager Marco Arts (left), CFO Dick van Deijck, researcher Dries van Eyk and Carbyon co-founder Simon Bambach.

The aim is that Carbyon will present a prototype of the machine halfway through 2021 that demonstrates how it filters CO2 out of the atmosphere. This entails a cylindrical device that can rotate. The film then captures the gas in a section of the cylinder – which is similar in shape to an oil drum. The gas is removed from another section. As such, Carbyon’s device is basically a small factory that produces pure CO2.

One idea that De Neve is now playing with is that multiple cylinders of e.g. 5 meters high and a diameter of 2 meters can be installed in places where CO2 is able to be extracted or used directly. The reason for this is that the transport of CO2 is expensive. In practice, this would be in places where industry emits CO2, and in places where CO2 can be transferred to a storage location.

As is the case with any innovation, Carbyon’s machine is expected to face a few hurdles along the way. For example, the extraction of pure hydrogen for converting CO2 into kerosene using Carbyon’s machinery is still costly. Consequently, before green kerosene can compete with fossil kerosene, that problem must first be solved, De Neve states. “But that’s what the companies that specialize in this are committed to doing. We specialize in extracting CO2 from the air and delivering it in a purified form at a cost-effective price.”

At the same time, it must become more appealing for industry to manufacture in a CO2-neutral way. If the permits to emit CO2 remain cheaper than filtering CO2 from the air, this is likely to disrupt the market for Carbyon.

Carbyon is not the only company that is developing a method to filter CO2 from the air. However, other companies such as Climeworks and Carbon Engineering Engineering use more energy in their processes. According to De Neve, this is mainly due to the high-temperature levels needed to convert the extracted CO2 back into a pure gas. Some companies require temperatures of up to 800 degrees Celsius for this. It takes a huge amount of energy to heat up to such a high temperature. In that respect, the machinery from Carbyon is a godsend.

The greatest gain would be if it were indeed possible to produce cheap green kerosene from CO2. Up until now, it has not been possible to develop a battery that is suitable for aircraft because batteries are still too heavy. This is an insurmountable problem, especially when it comes to long-haul flights. Hydrogen is contained in a tank that takes up a lot of space. This is also a problem because no passengers or cargo can be seated on the spot where the tank is installed. This method would therefore make seating a lot more expensive than it is now.

The alternative is that the aviation sector continues to fly on kerosene. If it does turn out that it is possible to fly on green kerosene, any CO2 emitted will be reused and, on balance, no new CO2 will be released into the atmosphere. Under those conditions, the likelihood that Carbyon will conquer the market is quite considerable.

Author: Innovation Origins